Ever wondered what’s going on inside those sturdy buttons you press every day? Metal push button switches with light or lock show up in all sorts of gear. They handle tough jobs. In this post, we’ll break down the internal structure. You’ll see how these parts work together. This knowledge helps if you’re building devices or fixing them. It builds your confidence in picking the right switch for your needs.

What Makes Metal Push Button Switches Stand Out

These switches aren’t just simple on-off tools. They pack features like lights for signals or locks for safety.

Basic Setup and Why It Matters

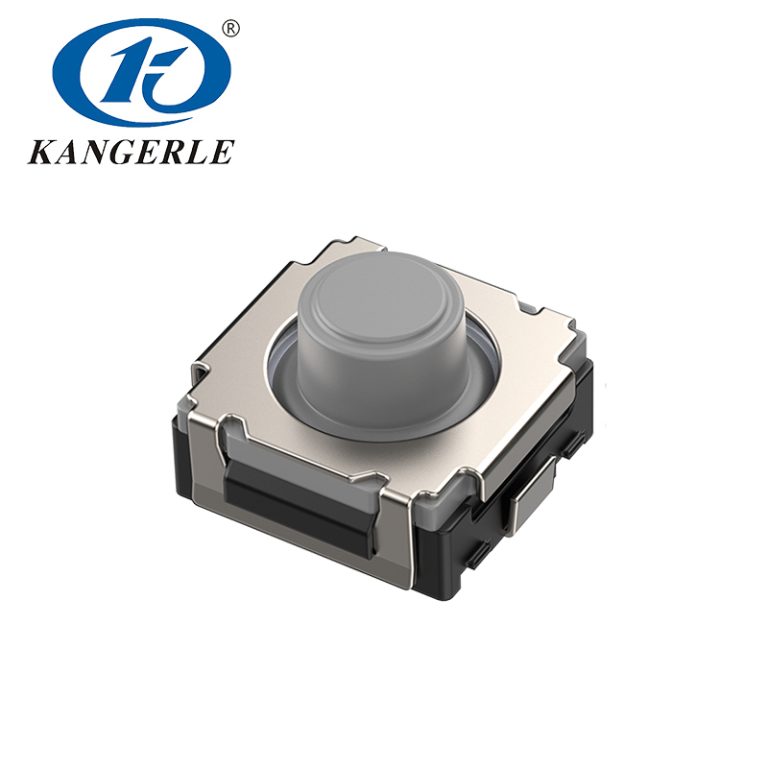

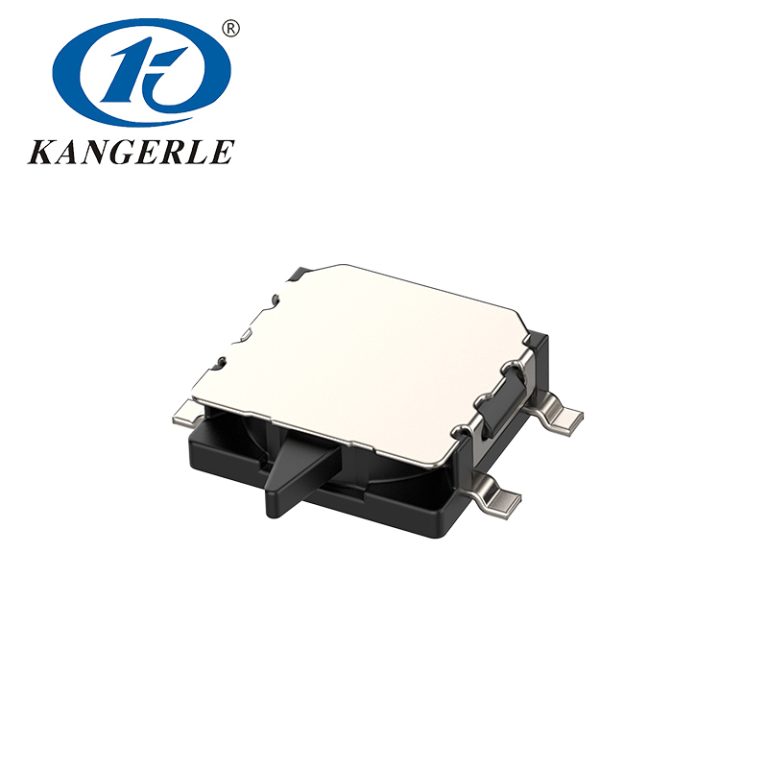

A metal push button switch feels solid under your finger. Push it, and it clicks. That click comes from inner parts working in sync. The outer shell is metal. It fights off wear and tear. Inside, things get interesting. People in fields like labs or medical tools rely on them. They need switches that last and respond fast.

Lights add a glow to show if it’s on. Locks keep it from accidental presses. Both boost how you use the device. Think of a machine in a busy workshop. The light tells you it’s ready. The lock stops mishaps.

Common Spots Where You Find Them

You spot these in home gadgets, cars, or safety gear. Labs use them for precise starts on machines. Medical devices count on them for quick actions. Even in everyday items like ovens or alarms. The internal structure keeps them reliable. No matter the spot, they handle presses without fail.

Peeking into the Internal Structure

Let’s get to the heart of it. The inside holds key bits that make the switch tick.

Main Components at a Glance

Start with the button top. It’s what you press. Below that, a metal piece sits ready. This piece moves when you push. It connects or breaks the flow. Simple, right? But there’s more.

A spring in the middle acts as a pivot. It bounces back after each press. This spring keeps things snappy. Over time, it might shift or wear. That can make the switch stiff. Plastic holders keep everything in place. They age too, leading to bends or breaks.

Wires run through. One key wire, the neutral one, goes straight. It doesn’t touch the main action. But if its cover wears, troubles start. Lights have their own pins. These can short if not set right.

Here’s a quick list of core parts:

- Metal actuator: The mover that links circuits.

- Spring fulcrum: Gives the bounce and reset.

- Plastic bracket: Holds shape and position.

- Wiring paths: Carry power without mix-ups.

- Light element: Glows for status checks.

- Lock mechanism: Stops unwanted presses.

Each part plays a role. Together, they make the switch tough and smart.

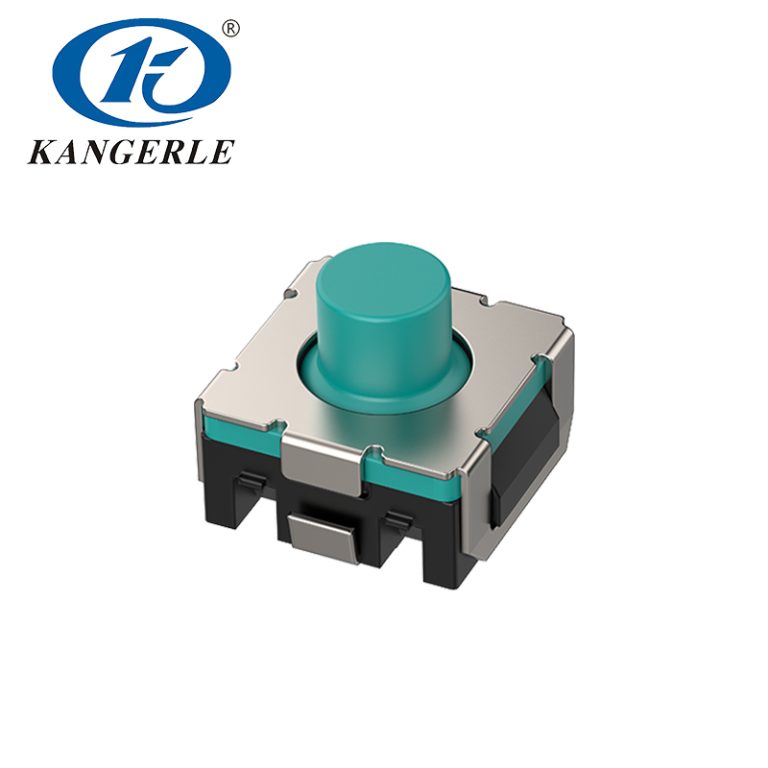

How Light Features Fit In

Lights bring visibility. Often an LED sits inside. It ties to the circuit. When on, it shines through the button. This shows power flow or mode. The internal structure links the light pin to the main setup. If there’s a short here, the whole thing might trip.

Why add light? In dim spots, it guides you. Or signals errors. The structure keeps it safe from dust or bumps. Press the button, and the light reacts right away.

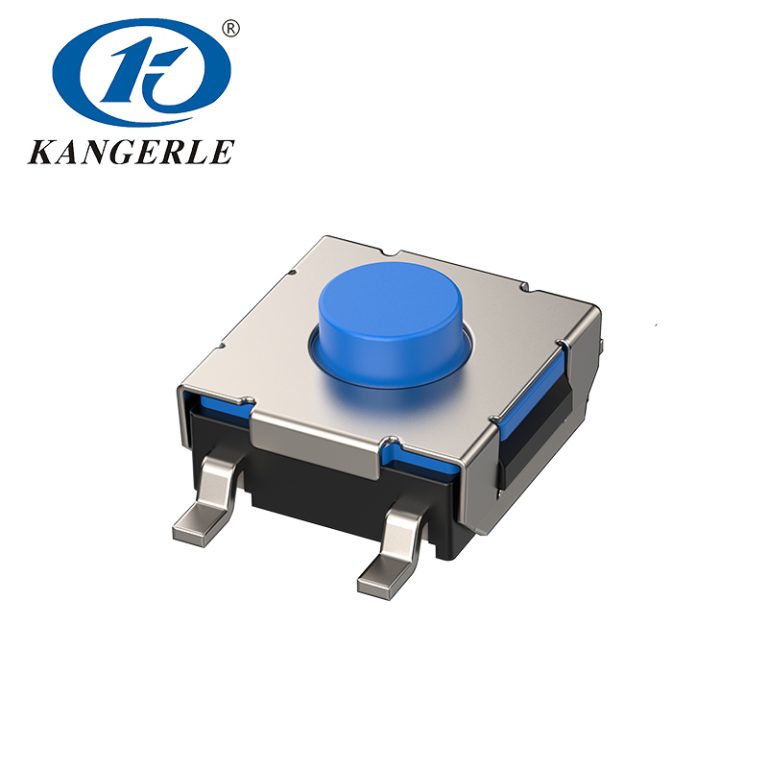

The Lock Mechanism Explained

Locks add control. A twist or extra push engages it. Inside, a catch holds the button down. Or up, depending on type. This stops slips in key moments. The internal structure uses metal hooks or slides for this. They mesh with the spring and actuator.

In safety gear, locks prevent starts by mistake. The design keeps it simple yet firm. No extra bulk.

How the Parts Work Together

It’s not just a pile of bits. They team up for smooth action.

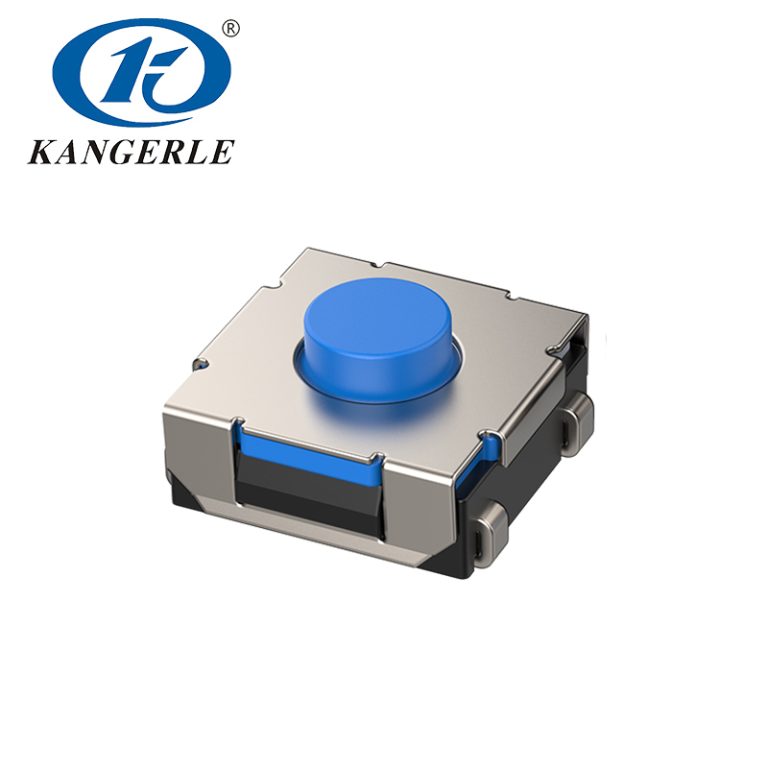

The Press and Release Cycle

Push down. The metal piece shifts. It presses the spring. Contacts meet, flow starts. Release, and spring pops back. Contacts part. Light might flip on or off. Lock holds if set.

This cycle repeats thousands of times. The internal structure handles the stress. Metal fights corrosion. Plastics stay flexible. Wires keep insulated.

If things go wrong? Stiff feel means spring issues. No click? Bracket might be bent.

Handling Power and Signals

Power runs through contacts. They need clean meets. Insulation stops leaks. The neutral wire bypasses the action. But damage here causes jumps.

Lights draw little power. Their pins connect separate. This setup keeps the main job clear.

In devices, this means steady work. No flickers or fails.

Challenges and Fixes in the Internal Structure

No part lasts forever. Knowing common snags helps.

Wear and Tear Issues

Springs lose bounce over years. Brackets deform from heat or force. Wires fray.

Signs? Switch sticks. Or jumps power. Light dims.

Fix it by checking inside. Power off first. Open up. Look at spring and bracket. If whole, reset them. Cut bad wire parts. Reconnect firm.

Table of common problems and quick checks:

| Issue | Likely Cause | Simple Check |

| Stiff press | Spring shift or bracket bend | Open and inspect for deformation |

| Power jump | Wire insulation damage | Trace neutral wire for breaks |

| Dim light | Pin short | Test connections with meter |

| No lock hold | Mechanism wear | Clean and align catches |

These steps keep things running. Regular looks extend life.

Safety Tips for Handling

Always cut power before opening. Use tools that fit. Note wire spots. This avoids new troubles.

In pro settings, this builds your rep. Fix fast, devices stay up.

Real-World Uses and Benefits

See how this structure shines in action.

In Lab and Medical Gear

Labs need precise starts. The internal structure gives quick response. Lights show ready. Locks prevent errors.

One case: A machine spins samples. Button starts it safe. Structure handles vibes without fail.

Medical tools save lives. Defibrillators use these for sure presses. Light guides in rush. Lock secures modes.

Everyday and Industrial Spots

Homes have them in appliances. Push to start cycles. Structure fights daily use.

Factories count on toughness. Metal shell plus inner strength means less down time.

This reliability lifts your work. Devices perform. Your brand grows strong.

Picking the Right Switch for Your Needs

Choose based on what you face.

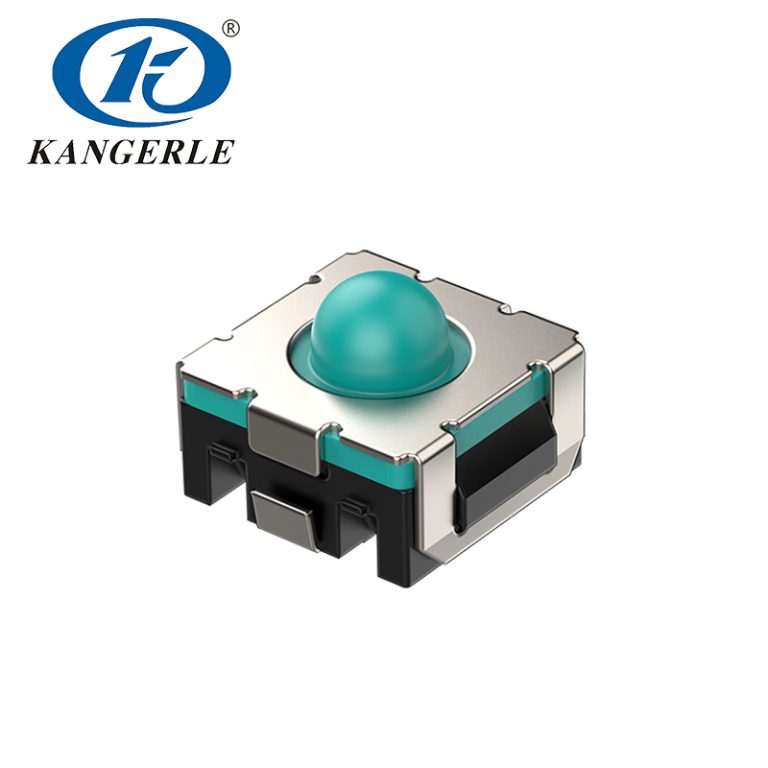

Factors to Weigh

Think load. How much power? Structure must match.

Environment. Damp or dusty? Seals help.

Features. Need light for signals? Lock for safety?

Certifications matter. They show tested quality.

Talk to makers. They guide on fits.

Zhejiang Kangerle Electronics Co., Ltd: Your Metal Push Button Switch Supplier

ZHEJIANG KANGERLE ELECTRONICS CO. LTD serves as a key supplier for metal push button switches. Set up in the early 1990s in Wenzhou, China, they make parts for safety, home tools, and more. With a team of over 20 engineers and strong output, they hold top marks for quality. Their focus helps you get switches that fit and last.

Conclusion

The internal structure of metal push button switches with light or lock keeps them vital in many fields. It blends strength with smart features. By grasping this, you make better choices. This boosts your setups and trust in them. Dive in, and see the difference.

FAQs

What key parts make up the internal structure of a metal push button switch with light or lock?

Core bits include a metal actuator, spring pivot, plastic holder, wires, light pins, and lock catches. They work as a team for reliable presses.

How does the light in the internal structure of a metal push button switch with light or lock function?

The light, often an LED, links to the circuit. It glows to show status. Pins connect separate to avoid mix-ups with main flow.

Why might a metal push button switch with light or lock become stiff, based on its internal structure?

Springs shift or brackets bend over time. This affects bounce. Open and check to fix.

Can you fix issues in the internal structure of a metal push button switch with light or lock yourself?

Yes, for simple ones like wire damage. Power off, inspect, and reconnect. For complex, seek pros.

How does the lock affect the internal structure of a metal push button switch with light or lock?

It adds catches that hold position. This meshes with spring and actuator for safe holds without extra hassle.