Floor scrubbers handle tough cleaning jobs across warehouses, hospitals, and factories, where wet floors and constant movement demand equipment that stays safe and functional. Grounding status detection plays a key part in this, signaling when the machine’s brushes or pads make solid contact with the surface to start scrubbing without slips or uneven results. This blog dives into how waterproof micro switches like the WS1-10A-B tackle these challenges, boosting machine performance and cutting down on downtime in real cleaning setups.

Understanding Grounding Status in Floor Scrubbers

Grounding status means the point when a floor scrubber’s cleaning head meets the floor solidly. This starts the system. It turns on motors, lets out water, or gets brushes going. If detection misses the mark, machines could work poorly. They might waste power or miss dirty spots. And that pushes up costs in big jobs, like in stores that cover thousands of square feet each day.

Busy spots add to the trouble. Think of a shipping hub. Floors there get lots of steps and messes. Bad grounding detection causes extra trips over the same ground. This holds up crews. It also wears down pieces faster. But good switches fix these snags. They give fast, exact info to the control setup. So the scrubber runs only when it’s down all the way.

This call for solid parts opens the door for special switches. They hold up against wet stuff and dirt. At the same time, they send steady signs.

The Role of Waterproof Micro Switches in Detection

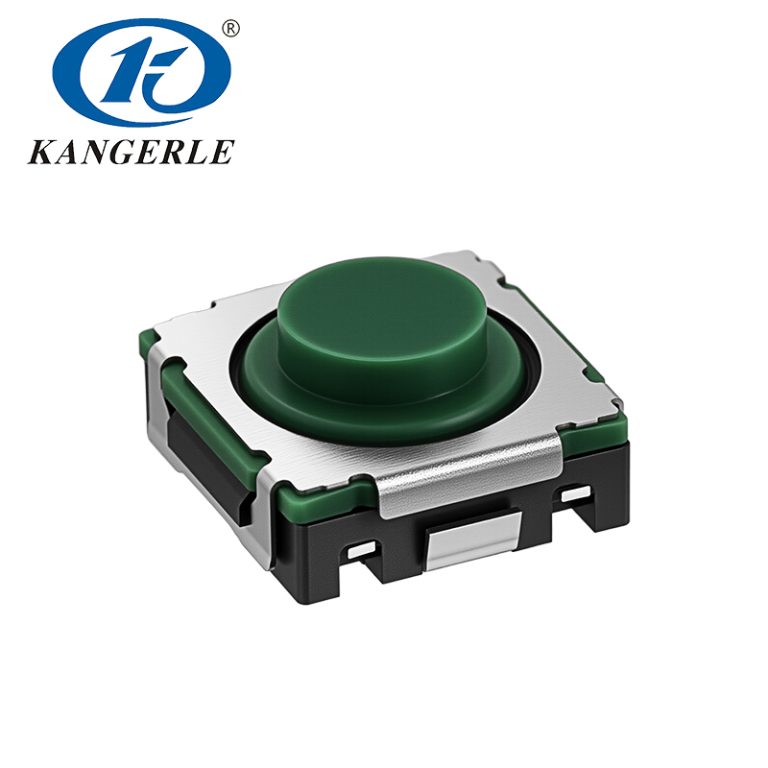

Waterproof micro switches fit perfectly in floor scrubbers because they handle the splash of cleaning solutions and the grit from debris without failing. These small devices act as sensors, closing or opening circuits based on physical contact, which in this case detects if the scrubber is properly grounded on the floor.

The WS1-10A-B model stands out for its sealed design that keeps water out during high-pressure washes or accidental submersion in puddles. Operators in food processing plants, where hygiene rules require frequent rinsing of equipment, rely on such switches to maintain uptime without electrical shorts.

Key Features of the WS1-10A-B

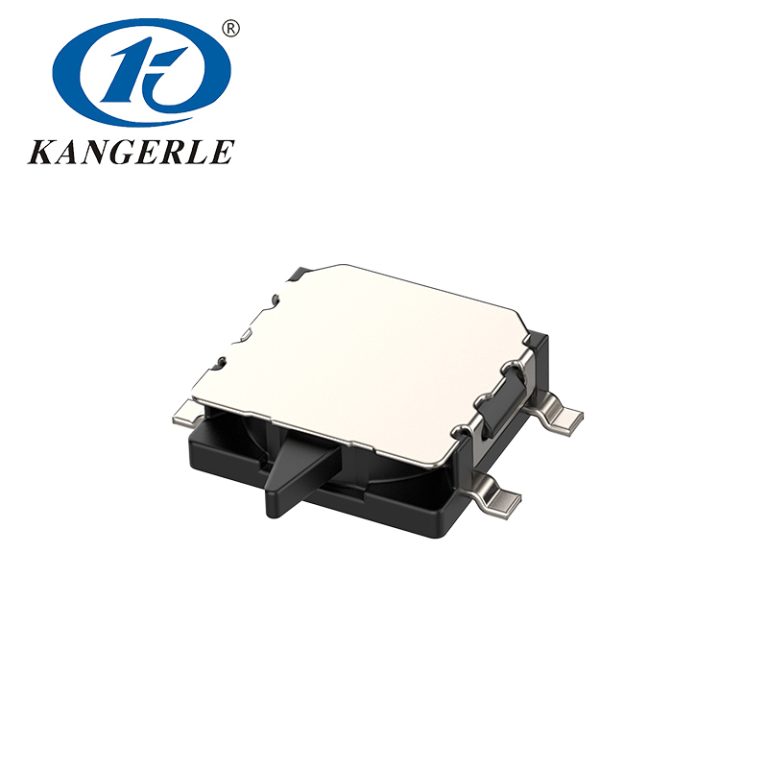

Built for harsh conditions, the WS1-10A-B combines compact size with robust protection. Its hermetically sealed body prevents ingress of liquids, making it ideal for wet applications like floor scrubber grounding detection.

Here’s a breakdown of its main specs in a table for clarity:

| Parameter | Details |

| Rated Load | 5/10A at 125/250V AC |

| Temperature Range | -25°C to 125°C |

| Operating Force | ≤350gf (regular) |

| Circuit Options | SPDT, SPST NO, SPST NC |

| Protection Level | IP67 (wiring) |

| Electrical Life | ≥10,000/50,000 cycles |

| Mechanical Life | ≥1,000,000 cycles |

| Certifications | CQC, CB |

These features mean the switch responds fast to light pressure from the scrubber’s weight pressing down, sending a signal to start the cleaning cycle. In practice, this translates to smoother operations in places like airports, where scrubbers cover vast tiled areas overnight without interruptions from faulty sensors.

With these specs in mind, let’s explore how the switch integrates into the broader system of a floor scrubber.

Applications of WS1-10A-B in Real-World Cleaning Scenarios

In industrial cleaning, IP67 waterproof switches like the WS1-10A-B get mounted near the scrubber’s base or linkage arms to monitor contact. When the machine lowers its head, the switch actuates upon touching the ground, confirming grounding and allowing the flow of detergent or activation of rotating brushes.

Take a hospital maintenance routine: scrubbers navigate corridors soaked with disinfectants, and the WS1-10A-B detects uneven floors or ramps by its sensitive trigger, preventing the machine from spraying water prematurely and causing slips. Data from similar setups shows that switches with over a million mechanical cycles reduce replacement needs by half compared to standard models, saving on labor in facilities that run machines for 8-10 hours daily.

Another example comes from manufacturing floors coated in oil residues. Here, the switch’s high insulation resistance—greater than 100MΩ—guards against false triggers from conductive liquids, ensuring the scrubber only engages when fully grounded. This precision helps maintain consistent cleaning paths, avoiding streaks that could lead to safety hazards.

Benefits for Efficiency and Safety

Switching to reliable components elevates overall equipment performance. For instance:

- Reduced Downtime: With an electrical life spanning tens of thousands of cycles, the WS1-10A-B minimizes breakdowns during peak cleaning hours.

- Cost Savings: In a warehouse spanning 50,000 square feet, accurate grounding detection switchescut water usage by up to 20% by preventing unnecessary dispensing.

- Enhanced Durability: The compact, solder-terminal design simplifies repairs, allowing quick swaps without specialized tools.

These advantages build trust in the equipment, helping businesses meet strict cleanliness standards in regulated industries.

Moving beyond individual benefits, proper integration ties everything together for seamless use.

Integration and Maintenance Tips for Optimal Performance

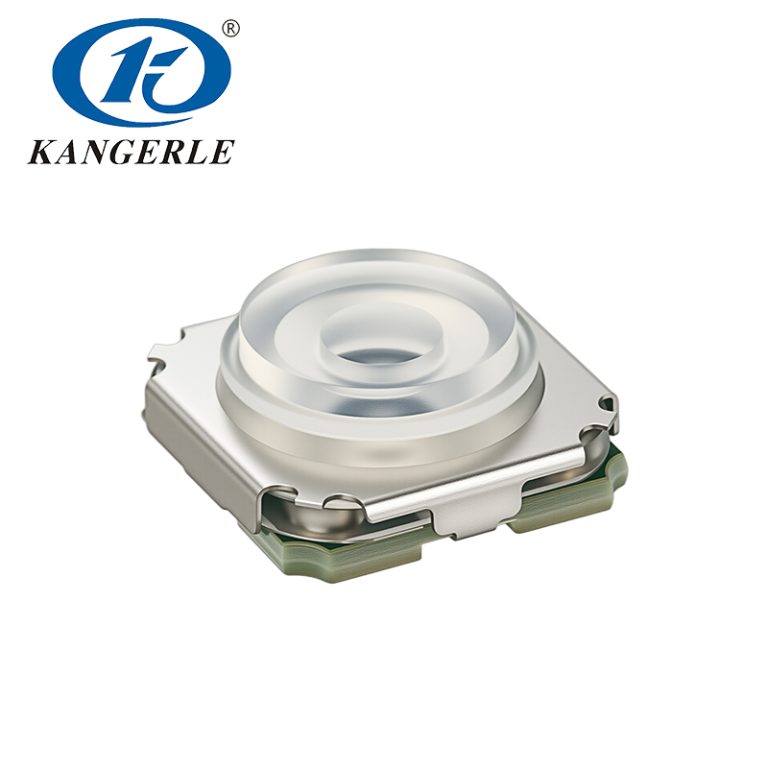

Installing the WS1-10A-B involves securing it to the scrubber’s chassis with brackets, connecting wires to the control board for signal relay. In wet environments, its IP67 rating means no extra enclosures are needed, unlike basic switches that require added seals.

Maintenance stays straightforward—regular checks for debris around the actuator keep it responsive. In a commercial kitchen setup, where scrubbers face grease buildup, wiping the switch monthly extends its life, backed by its withstand voltage of over 100VAC that handles power surges from nearby appliances.

This ease of use supports long-term reliability, making it a go-to choice for upgrading older scrubbers.

Meet ZHEJIANG KANGERLE ELECTRONICS CO. LTD

As a trusted supplier in this field, ZHEJIANG KANGERLE ELECTRONICS CO. LTD delivers high-quality waterproof micro switch solutions. Founded in the early 1990s in Wenzhou, China, the company specializes in electronic components for appliances, automotive, and industrial sectors. With over 20 years of experience, it holds ISO9001:2015 and IATF16949 certifications, producing more than 50 million pieces monthly. Their focus on stability and innovation ensures products like the WS1-10A-B meet global standards through advanced testing and custom options.

Conclusion

The WS1-10A-B proves essential for precise floor scrubber grounding detection, blending waterproofing with sensitive actuation to handle demanding cleaning tasks. Its role in boosting safety and efficiency underscores why such switches matter in modern equipment, helping operations run smoother and longer.

FAQs

What makes the WS1-10A-B suitable for waterproof micro switch applications in floor scrubbers?

Its IP67 protection seals out water and dust, while the compact design fits tight spaces near the grounding mechanism, ensuring reliable detection even in soaked conditions.

How does grounding status detection work with these switches?

The switch actuates on contact, sending a signal to the control system to confirm the scrubber is grounded before starting brushes or water flow, preventing errors in wet areas.

Can the WS1-10A-B handle custom needs for floor scrubber designs?

Yes, with options for different circuits and forces, it adapts well; the company offers ODM/OEM services for tailored fits.

How to get support for integrating WS1-10A-B into a floor scrubber?

Reach out via email or phone for samples and advice; quick responses help with setup. Contact details are at Contact Us.