In the world of industrial machinery, dust moves fast. Water hits hard. Shakes happen often. Here, being steady matters a lot. It’s not only useful. It’s required. Imagine plants packed with large tools. Or places outdoors dealing with storms. That’s where waterproof micro switches fit in. These small pieces act like silent watchers. They make sure machines operate without problems, even in difficult spots. If you handle production or repair work, you understand. A minor issue can pause entire setups. Or lead to big expenses from idle time. This writing explores how these switches appear in industrial areas. They improve steadiness in hard places. We’ll examine actual cases, plus points, and methods to select the proper ones for your tasks.

Understanding Waterproof Micro Switches

Let’s begin easy. What do these switches involve? In short, micro switches turn on or off quickly with a touch. The waterproof sort raises the level. They shut out liquid, grime, and other trash that might ruin ordinary switches.

What Makes Them Waterproof?

Many times, these switches carry strong IP levels. Such as IP67 or above. This shows they can stay under water or endure dirt blasts without issues. Within, closed covers from durable plastics or metals handle the work. Rubber seals block harmful items. It’s smart construction, not mystery. As an example, the contacts remain free of wet. This halts decay that damages function as days pass.

Why is this important? In work zones, machines meet rain, drips, or moist air daily. A switch lacking waterproof traits could perform well in a spotless space. But place it in a damp storage area, and it stops shortly. The waterproof types endure more. They reduce mends. And they maintain smooth flow.

Basic Working Principle

See it like this. A push rod or handle receives force. It activates a loaded spring that changes the contacts swiftly. It’s rapid and spot-on. In poor conditions, this constant action ensures detectors find locations correctly. Handles reply without holdup. Protection measures begin exactly when necessary. No delay. No confusion.

Applications in Industrial Machinery

All right, now the core section. How do these switches show in real work tools? They’re in many places. From assembly paths to heavy vehicles. They perform quietly to hold things steady.

In Automation and Robotics

Robots in facilities grab objects. They fuse metal. They construct items without pause. In this case, waterproof micro switches detect final positions or spot things. For example, a mechanical arm reaches its boundary. The switch signals a stop. This avoids damage. In moist or gritty workshops, like food handling areas with frequent rinses, these switches dismiss the liquid. What results? Fewer halts. Extra running hours.

Consider a moving belt setup. Switches observe belt strain or object spots. If rinse water enters, a basic switch could corrode and freeze. Yet waterproof ones continue firmly. They guarantee the path remains open.

Heavy Equipment and Outdoor Use

Outdoors, conditions turn stricter. Construction devices like earth movers or hoists encounter sludge, downpours, and sharp temperature shifts. Waterproof micro switches manage fluid systems or security blocks. For instance, they verify a hatch is secure before the device activates. Or they halt energy if a fault occurs.

In extraction tasks, powder is dense. Liquid jets are constant. These switches in boards or detectors remain solid. They prevent incorrect alerts from buildup. This protects workers. And keeps devices active.

Specialized Industrial Sectors

Different zones hold unique requests. In chemical facilities, switches resist biting vapors beside dampness. Ship equipment employs them for surface handles. They combat salty fog. Even in clean energy, like wind turners, they manage gusts and showers. Meanwhile, they observe blade locations.

- Food and Beverage Industry: Switches in wrapping devices face usual scrub downs.

- Automotive Manufacturing: They notice part arrangements in assembly bots. They ignore grease spills.

- Pharmaceuticals: Areas with strict hygiene apply them for device handles. They remain shut against purify solutions.

Every zone demonstrates how these switches adjust. They confirm their importance in maintaining tools consistent.

Benefits for Reliability in Harsh Environments

Shifting to waterproof micro switches extends past defeating liquid. It’s about succeeding in disorder. Here’s the reason they excel.

Enhanced Durability and Longevity

These switches become constructed firm. Materials such as sturdy steel or reinforced blends oppose harm. In trembling devices, they stay fixed without slack. Exams reveal they manage countless turns without failure. They surpass uncovered versions greatly.

Envision a pump in a sewage handling location. Ongoing damp might finish a standard switch in weeks. Waterproof ones? They persist for seasons. This lowers exchange expenses.

Improved Safety Features

Protection leads, correct? In severe zones, dependable switches provide accurate responses. They launch sudden halts if force rises or locations move wrongly. No liquid-caused faults mean no abrupt device moves that might injure individuals.

Moreover, they match guidelines like UL or CE. This offers assurance that they’re examined for difficult applications.

Cost Savings Over Time

Initially, they could demand additional funds. But consider the future. Reduced idle periods equal greater output. Scarcer repairs decrease labor charges. In a single report from a production group, switching to waterproof types lessened upkeep by 30%. That’s genuine economy.

| Benefit | Description | Impact on Operations |

|---|---|---|

| Durability | Battles liquid, powder, and jolts | Extends device lifespan, lessens repairs |

| Safety | Halts incorrect cues from filth | Reduces injury risks, maintains standards |

| Efficiency | Swift, consistent shift | Increases output, diminishes pauses |

| Cost-Effectiveness | Extended duration in poor areas | Decreases overall spending, enhances payoff |

This list captures it. Gains everywhere.

Choosing the Right Waterproof Micro Switch

Selecting varies per situation. Reflect on your arrangement.

Factors to Weigh

Commence with the surroundings. How soggy? How filthy? Align the IP grade to that. Next, power aspects like flow strength. Physical elements like press power matter as well. Too rigid, and it fails to activate properly.

Space dimensions count in narrow areas. And remember attachment—bolt or latch?

Integration Tips

While adding to devices, experiment in actual scenarios. Create pretend showers or tremors. Partner with providers who supply tailored adjustments to suit ideally.

Typical errors? Overlooking warmth ranges. Certain switches cope with -40°C to 85°C. Others cannot. Constantly verify.

Maintenance Best Practices

Even robust switches desire attention. Routine checks identify erosion soon. Clean mildly, avoid strong mixtures that could damage barriers. Record turns to forecast changes.

Through wise selection, you secure consistency.

Challenges and Solutions

No item functions flawlessly. Difficult locations present unexpected turns.

Common Issues

Intense chill can harden components. Abundant moisture could creep beyond barriers gradually. Tremors relax links.

Overcoming Them

Designs with superior cushion manage motions. Superior barriers contest moisture. For chill, heated varieties exist.

Fresh concepts like auto-clean touches or cable-free selections reduce erosion further.

Remaining current involves observing shifts. Novel materials render switches yet firmer.

Future Trends

Forward, these switches advance. Intelligent models with web connections observe their condition. They predict malfunctions. Nature-friendly substances lessen harm to the earth.

In modern production methods, they’ll assume larger roles in connected facilities. They guarantee smooth info transfer even in poor zones.

For firms, adopting these signifies remaining competitive. Consistent and prepared for whatever arrives.

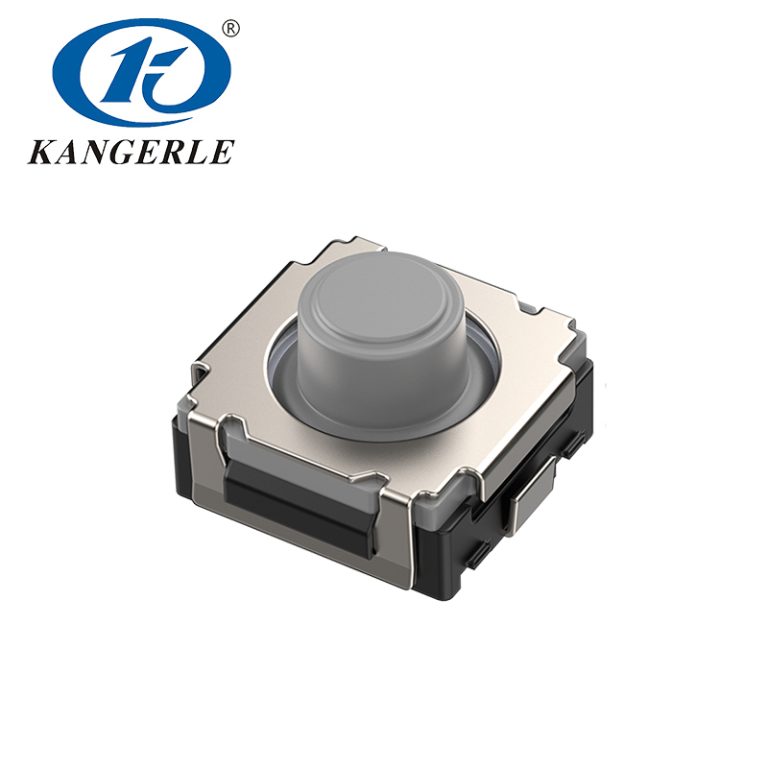

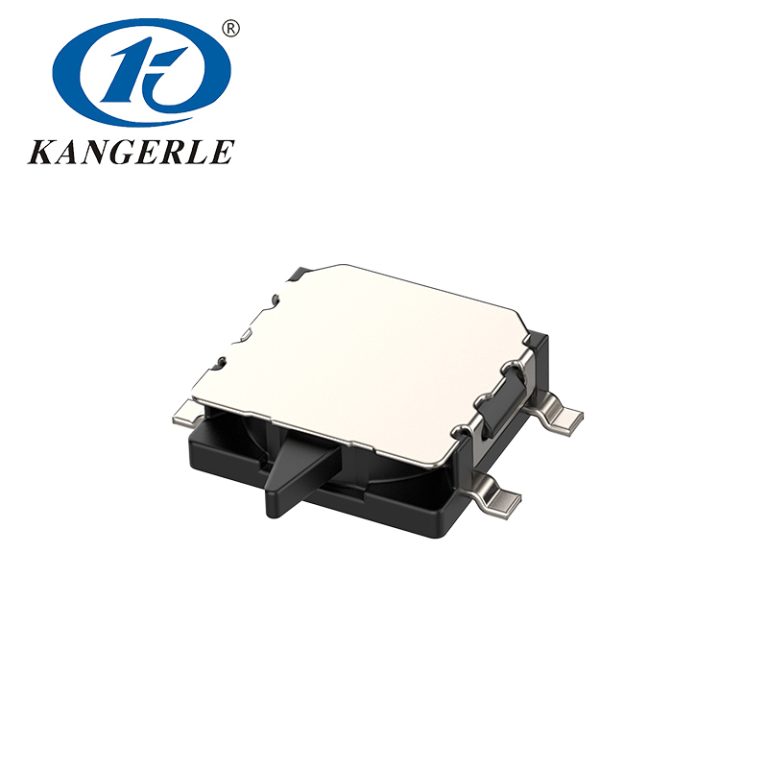

Who Is ZHEJIANG KANGERLE ELECTRONICS CO. LTD?

Before closing, let’s mention a primary provider in this domain. ZHEJIANG KANGERLE ELECTRONICS CO. LTD focuses on waterproof micro switches. They draw from extensive experience to aid international customers. Established in a core of electronic production, they target superior creation with modern equipment and rigorous evaluations. Their staff manages everything from blueprint to shipment. They tailor resolutions for sectors like household devices, vehicles, and medical tools. Dedicated to fresh concepts and client desires, they produce switches that endure in demanding areas. Supported by documents that demonstrate their dependability. Whether you expand or alter blueprints, their ODM/OEM assistance simplifies obtaining what suits.

Conclusion

Waterproof micro switches emerge as vital elements in industrial machinery. They assist equipment to remain reliable in harsh environments. From strengthening toughness to lowering expenses and upgrading protection, they offer actual benefits. As work areas seek greater pace, these elements will continue to develop. They support easier operations. If you confront challenging areas, pondering them might alter your arrangement’s performance significantly.

FAQs

What role do waterproof micro switches play in industrial machinery?

These switches detect locations, manage tasks, and maintain security in devices. Utilized in industrial machinery, they preserve operations stable by overcoming liquid and powder. This helps to ensure reliability in harsh environments like damp facilities or exterior locations.

How do waterproof micro switches ensure reliability in harsh environments?

They employ sealed structures to prevent damp and debris, stopping faults or decay. This suits them for areas with splatters, tremors, or grime. It allows equipment to proceed without interruptions.

Can waterproof micro switches be customized for specific industrial needs?

Yes, numerous providers offer alterations in dimensions, force, or materials. This permits them to integrate seamlessly into varied devices. It elevates their capacity to ensure reliability in harsh environments.

Why switch to waterproof micro switches from standard ones in industrial settings?

Basic switches fail rapidly in tough areas, resulting in downtime. Waterproof varieties endure longer and function superior. They become a clever option for utilized in industrial machinery where consistency is crucial.

Are there maintenance tips for waterproof micro switches in harsh environments?

Examine frequently for barrier erosion, clean softly, and monitor usage. This basic care assists them to persist in ensuring reliability in harsh environments for extended periods.