Disc brake switches are key parts in electric scooters. They act as the link between the physical brakes and the scooter’s electronic brain. They sense when the rider pulls the brake lever. Then, they quickly tell the controller to stop motor power. They also turn on safety features like brake lights or energy-recovery braking. These switches are carefully made to last and handle tough conditions. This ensures they work well in all kinds of riding situations. Companies like ZHEJIANG KANGERLE ELECTRONICS CO. LTD focus on top-notch designs. These designs meet strict safety rules and fit many scooters. This makes riding safer and scooters work better.

What Job Does a Disc Brake Switch Do in Electric Scooters?

Electric scooters use both physical parts and electronic systems. This mix keeps riders safe and makes braking work right. The disc brake switch is very important here. It makes sure the braking action works together with the scooter’s electronic controls.

How the Disc Brake Switch Works

The disc brake switch works like a sensor. It notices when the rider squeezes the brake lever. As soon as this happens, it sends a message. This message goes to the scooter’s main controller. It tells the controller to start the braking steps. This includes turning off the motor power. In some models, it also switches on the brake lights. It might even start systems that capture energy during braking. Electric Bike/Motorcycle Brake Light setups often use these switches. They turn on the rear lights whenever braking starts.

How the Brake Switch and Electronic Braking Talk to Each Other

Modern electric scooters don’t just rely on physical brakes. The disc brake switch connects with electronic braking systems (EBS). These smart systems use computer rules. The rules manage how the motor resists and how energy is captured back. When the switch is pressed, it tells the controller to lower the electricity going to the motor. It might also turn on the energy recovery. This teamwork makes stopping smoother. It also helps the battery last longer.

Why Proper Brake Switch Operation Matters for Safety

A disc brake switch that breaks can cause big safety problems. It might fail to stop motor power when braking. Or, it might not turn on warning lights for cars behind. Electric Bike/Motorcycle Brake Lights are extremely important. They make the rider visible when slowing down. This is especially true in busy cities. A trustworthy switch makes sure these systems react instantly. They work the same way every time.

ZHEJIANG KANGERLE ELECTRONICS CO. LTD tackles these problems. They design KW2-1A-1B-B series of disc brake switches with exact trigger points. Their switches give steady signals. They also fit strongly with both lighting circuits and motor control systems.

How Is a Disc Brake Switch Built for Top Performance?

Making a great disc brake switch needs focus. It must be tough physically. It needs electrical dependability. And it must stand up to weather and bumps.

Parts Inside a Common Disc Brake Switch

A typical disc brake switch has several pieces. There’s an actuator lever. It has a spring mechanism. It includes contact terminals. And everything sits inside a protective housing. The inner contacts are set up to open or close an electrical path. This happens with only a tiny lever movement. This small size lets it fit into tight handlebar spaces. It doesn’t add bulk. It also doesn’t get in the way of other controls.

Electrical Needs for Electric Scooters

Disc brake switches must handle low-voltage DC signals. Scooter control systems usually use these – often 5V or 12V. Contact resistance should stay very low over years of use. This makes sure the signal passes accurately. There should be no voltage drops. Also, switches are made to “debounce”. This stops false signals caused by vibration or quick presses.

ZHEJIANG KANGERLE ELECTRONICS CO. LTD proves their KW2-1A-1B-B series meets these needs. They test hard. They check contact resistance stays stable. They test how the switch holds up to repeated pressing. This mimics real riding.

Why Is Exact Engineering So Important for Brake Switches?

Good engineering is the base. It affects both safety and how well parts fit together in electric scooters.

How Tiny Differences Affect Safety and Dependability

Tight building rules mean switches act the same every time. If the trigger force or timing changes, braking might be slow. Or motor cutoff might be inconsistent. Both are major safety worries. Riders face this in crowded traffic.

Fitting with Control Systems and Energy-Recovery Braking

More electric scooters now use regenerative braking. This makes exact timing even more vital. The moment the brake lever moves must match the start of electronic slowing. They need to sync within milliseconds. This gives the best energy capture. It also makes stopping feel smooth.

Problems in Demanding City Riding

City riding needs fast speeding up and slowing down. It involves constant stop-and-go use. Here, even small switch problems can cause rider unease. Over time, repeated stress might lead to system errors.

ZHEJIANG KANGERLE ELECTRONICS CO. LTD fixes these issues. They use strict quality steps during assembly. This includes machine checks for calibration. They keep micro-level sameness across every unit they ship worldwide.

How Do Weather and Dirt Change Brake Switch Design?

Disc brake switches sit on handlebars or near wheels. They face tough outdoor conditions. They must keep working well for a long time.

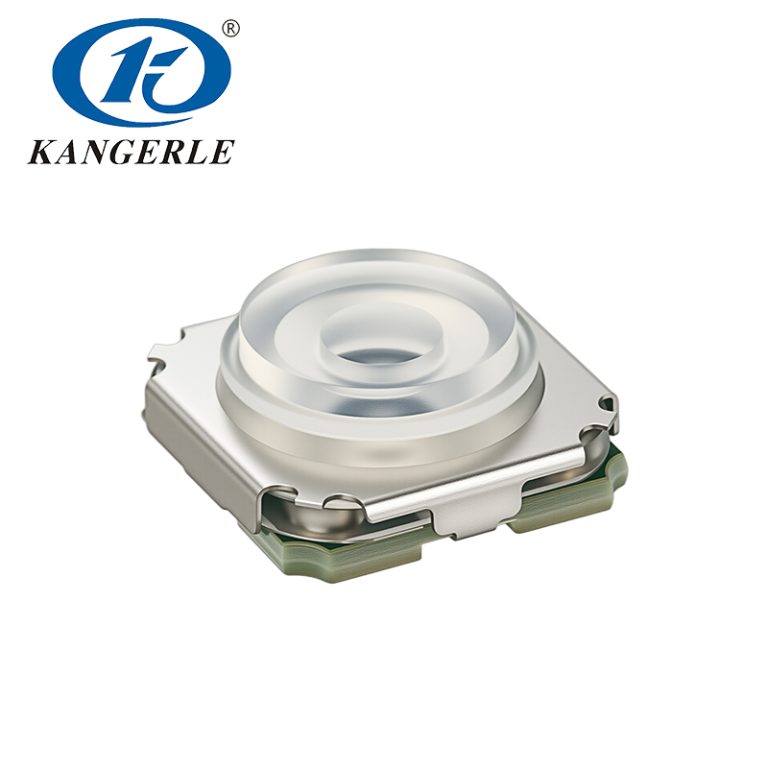

Fighting Water, Dust, and Shaking

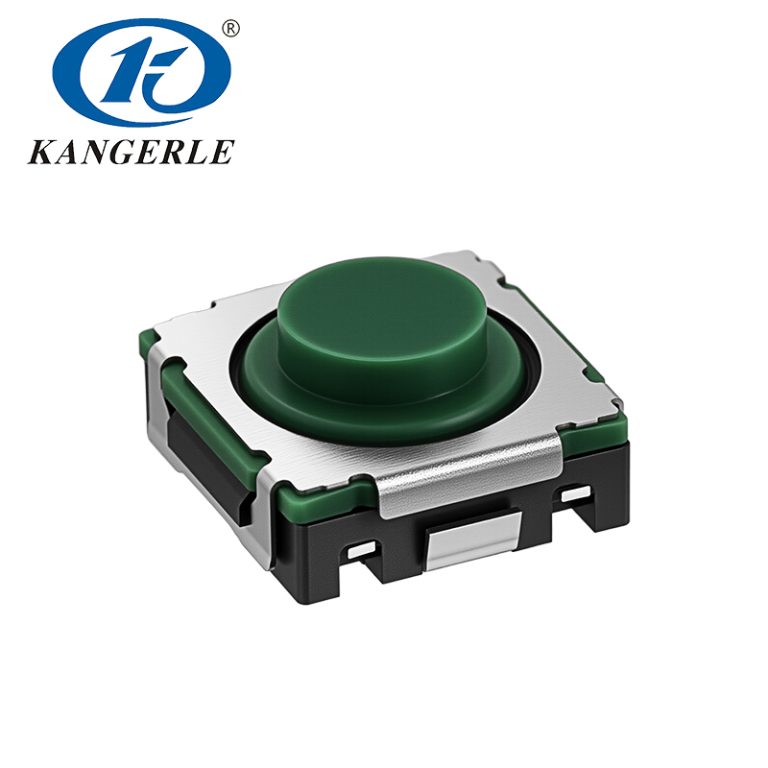

Switches face rain splashes, road grit, and constant bumps. Electric Scooter/Electric Bike Disc Brakes work here. So their electronics, like switches, must be just as tough. Rubber seals around the case edges help. Special coatings on inner circuit boards shield them. This stops water or dirt getting inside. That prevents shorts or rust damage.

Handling Heat and Cold Outdoors

Brake switches must work from very cold (-20°C) to very hot (60°C). These are normal weather changes worldwide. Spring and contact materials are chosen carefully. They account for how much parts expand with heat. This stops warping over long exposure.

Meeting Waterproof Ratings and Industry Rules

To prove toughness, makers often get certifications. These are IP ratings like IP65 or IP67. The rating depends on what the scooter needs. These standards confirm protection against water sprays or even dunking. This is absolutely key for scooters used outdoors all year.

ZHEJIANG KANGERLE ELECTRONICS CO. LTD checks their products. They use outside labs for tests matching world rules like CE. They get IP certifications made for mobility gear.

What Should You Think About When Choosing a Disc Brake Switch?

Picking the right disc brake switch means looking at tech details. You must also check it meets rules for your scooter model.

Fitting Your Scooter Model and Controller

Different scooter models might use different voltages. Or they might have different plugs. Making sure the switch model (like KW2-1A-1B-B) fits your controller’s software is essential. Then it plugs right in. You won’t need extra wiring changes.

How Long the Switch Should Last Mechanically

Shared scooters or daily riders use brakes a lot. So switch life is critical. A rating of 100,000 presses is standard. But better models can go beyond 500,000 presses in tests. They keep working perfectly.

Needed Certifications (RoHS, CE, etc.)

RoHS compliance means no bad stuff like lead or mercury. Scooter makers worldwide want this for the environment. CE certification also promises EMC performance. This matters because scooter electronics are packed close.

ZHEJIANG KANGERLE ELECTRONICS CO. LTD helps makers. They offer certified parts tested beyond normal life. They also meet world rules in different places.

How Does ZHEJIANG KANGERLE ELECTRONICS CO. LTD Help with Steady Supply?

ZHEJIANG KANGERLE ELECTRONICS CO., LTD has years of experience. They make electrical and mechanical parts. They offer full answers made just for electric scooters around the globe.

Looking at the KW2-1A-1B-B Line

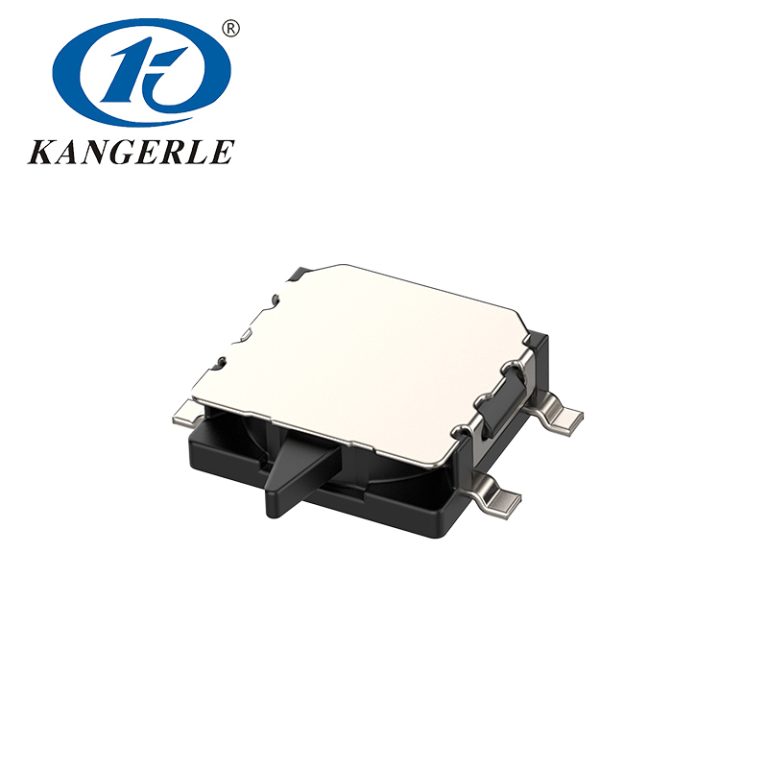

The KW2-1A-1B-B series is small. It fits easily on handlebars. Its contacts are silver-plated. This gives low-resistance signals even after heavy use in damp cities.

Promise to Quality Making

Every unit gets machine testing. This maps how it presses and activates. This ensures batches have zero faults. They are ready for big maker orders needing steady real-world use. No fixing after install is needed.

Worldwide Supply for Makers and Sellers

They have storage spots across Asia-Pacific. They partner with fast shipping firms worldwide. ZHEJIANG KANGERLE ELECTRONICS CO., LTD promises on-time delivery. This fits the “just-in-time” making big scooter brands use. They are growing fast in new markets.

Final Thoughts

Disc brake switches are fundamental in electric scooters. Here, physical action joins electronic smarts. Their job is more than just closing a contact. They act as guardians. They make sure slowing down happens safely. They also allow smart features like getting energy back. From weatherproof cases (IP-rated) to exactly timed signals for control – what these parts must do keeps growing. It grows with next-generation mobility.

FAQs About Disc Brake Switches for Electric Scooters

What makes a disc brake switch right for electric scooters?

A good switch works with low voltage (usually 5V–12V). It lasts through many presses (over 100,000). It keeps out water and dust (IP65+). And it fits easily with controllers managing EBS or energy recovery.

Can I swap a disc brake switch without hurting scooter performance?

Yes – if you use the exact same model. Match the voltage, plug type, press force, and certifications (like CE/RoHS). A wrong switch might cause slow braking or controller mistakes.

How long does a normal brake switch last with regular riding?

Quality switches made for electric scooters usually last 100,000 to 500,000 presses. It depends how often you brake and your conditions. Think about dampness or road shaking.