Selecting the right metal push button switch is crucial for various electronic applications, ensuring optimal performance and functionality. With an array of options available in the market, considering specific factors can simplify the decision-making process.

Let’s start by briefly understanding the basic knowledge of metal push-button switches.

What is a Metal Push Button Switch?

A metal push button switch is a switching device used to control circuits, typically composed of a metal housing, button, and contacts. Its operation is simple, allowing the circuit to be connected or disconnected by pressing or releasing the button.

Metal push button switches possess characteristics such as waterproofing, dust resistance, durability, aesthetic appearance, ease of operation, and good tactile feedback. Nowadays, they are widely used in various fields including industrial machinery, instrumentation, automotive, electronic devices, and more.

How to Select a Metal Push Button Switch?

Metal push button switches come in various styles and functionalities. Choosing an appropriate switch depends on specific requirements. Here are key guidelines to help you choose a suitable metal push button switch.

1. Understanding Application Requirements

Identify the purpose and environment in which the switch will operate. Determine if it will be used indoors or outdoors, in high or low temperatures, or in environments exposed to moisture or dust. Different switches are designed to withstand specific conditions, such as IP65 metal push button switch, IP67, IP68, and IK10 metal push button switch. Higher IP and IK ratings signify better protection against dust, moisture, and other environmental factors.

2. Hole Diameter for Installation: How to Determine?

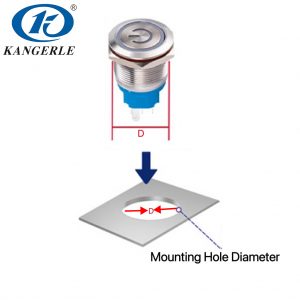

Consider the available space and the mounting options for the switch. Metal push button switches are typically installed on a panel, and the hole diameter refers to the installation hole’s size.

Check the dimensions and the panel cutout size required for installation to ensure compatibility with your setup. Commonly available hole diameters for metal push button switches include Φ6mm, Φ8mm, Φ10mm, Φ12mm, Φ16mm, Φ19mm, Φ22mm, Φ25mm, Φ28mm, Φ30mm, and Φ40mm.

3. Operating Type: Momentary or Latching?

Metal push button switches generally have two operation types: momentary metal push button switch and latching metal push button switch.

Momentary metal push button switch:

A momentary metal push button switch refers to a type of switch that operates in a manner where the electrical contact is only active or engaged while the button is physically pressed or held down. When the button is released, the switch returns to its original position, breaking the electrical circuit and ceasing the flow of current. For instance, metal push button switches momentary type are common in computer power buttons, car horn switches, and doorbell switches.

Latching metal push button switch:

A latching metal push button switch is a type of switch that maintains its state or position after being pressed until it’s intentionally actuated again to change its state. Unlike momentary switches, which only maintain the connection while the button is pressed down. A latching switch remains in its set position until deliberate action is taken to revert it to the opposite state. For example, latching switches are common in household light switches.

4. Switch Circuit Type of Metal Push Button Switch

As the most common electronic component, switches have normally open (NO) and normally closed (NC) circuit types. Metal push button switches come in circuit combinations such as 1NO, 1NC, 1NO1NC, and 2NO2NC. In simple terms, these indicate the availability of normally open, normally closed, or a combination of both in a metal push button switch.

– NO (Normally Open) metal push button switch: The contact remains disconnected when the button is not pressed; pressing the button connects the contact. It is commonly used as a start button.

– NC (Normally Closed) metal push button switch: The contact remains connected when the button is not pressed; pressing the button disconnects the contact. It is commonly used as a stop button.

– Combination metal push button switch: This type of switch comprises at least one set of NO contacts and one set of NC contacts combined. When pressed, the NC contacts disconnect first, followed by the NO contacts connecting. Upon release, the NO contacts disconnect first, followed by the NC contacts connect. This type is often used as an electrical interlocking switch, controlling multiple circuits.

Therefore, choose a metal push button switch with a corresponding circuit form based on your actual application.

5. LED metal push button switch or not?

Metal push button switches are available with or without LED lights. If an LED light is needed, the options include single-color LED, dual-color LED, and tri-color LED, depending on the application requirements. For LED metal push button switches, determining the required LED color and voltage is necessary. KANGERLE LED metal push button switches offer single-color LED lights in red, green, blue, yellow, white, orange, purple, and pink, dual-color lights in red-blue and red-green, and tri-color lights in red-green-blue and red-green-yellow. LED light voltage options range from AC/DC 3V, 6V, 12V, 24V, 36V, 48V, 60V, 110V, to 220V.

6. Symbols On The Metal Push Button Switch

KANGERLE metal push button switches have many types of symbols on the button. Ring LED, power symbol, ring power symbol, central single dots, and dozens of customizable symbols to meet diverse application needs.

7. Head Types of metal push button switches

Metal push button switches come in various head types, each designed for specific functionalities and applications. Here are some common head types of metal push button switches:

Flat Head: These switches have a flat, smooth surface on top, providing a sleek and modern appearance. They are commonly used in applications where a low-profile, flush-mounted switch is desired.

High Head: High head metal push button switches have a raised or elevated top surface compared to flat-head switches. They are easier to locate and press, making them suitable for environments where users might need to find and activate the switch quickly.

Round Head: Round head metal push button switches feature a circular button on the top. They are ergonomic and comfortable to press, often used in various applications due to their ease of use.

Mushroom Head: Mushroom head metal push button switches have a large, rounded button resembling a mushroom. These switches are typically used in emergency stop or safety applications due to their distinct shape that allows easy identification and quick access.

Knob Head: Knob head metal push button switches have a knob-like button on top, which can be turned or rotated. They are commonly used for applications requiring rotary control or adjustment, such as volume controls or setting adjustments.

Key Head: Keyhead metal push button switches resemble keys and often require a specific key for operation. They are used in applications where security and access control are crucial, such as in security systems or machinery requiring authorization to operate.

Each head type serves a specific purpose and caters to different user needs and preferences. The choice of head type depends on the intended use, ease of operation, required functionality, and the specific application where the switch will be utilized.

8. Housing Material of metal push button switches

The housing material of metal push button switches typically includes:

– Aluminum alloy: Has a lightweight, good heat dissipation, high strength, and corrosion resistance, albeit being more expensive, suitable for applications requiring lightweight and heat dissipation.

– Stainless steel: Features corrosion resistance, wear resistance, high-temperature resistance, hardness, and strength, providing excellent protective properties suitable for harsh environments and high-demand applications. The cost-effectiveness of stainless steel metal push-button switches is relatively higher.

– Brass: Offers good conductivity and heat dissipation, high strength, corrosion resistance, and cost-effectiveness, suitable for applications requiring good electrical and thermal performance.

Different casing materials for metal push button switches offer various advantages, enhancing performance and protection.

9. Terminal Types of Metal Push Button Switches

The most common terminal types for metal push button switches are two: plug terminals(equipped with optional connectors) and screw terminals. There are also less commonly used ones like pin terminals and integral types of metal push button switches. Below, we’ll explore their respective advantages and disadvantages.

| Terminal Type | Definition | Advantages | Disadvantages |

|

Plug terminal

|

Metal plug terminals that can be inserted into sockets or holes on circuit boards |

Rapid insertion or removal, easy installation and disassembly, time-saving; multiple types and sizes compatible with various devices and connectors; lower resistance and higher current capacity ensuring reliable electrical connections |

Additional space often required, unsuitable for compact applications; may loosen or bend over time, leading to poor insulation or circuit short-circuits |

|

Screw terminal

|

Metal screws terminals that can be tightened or loosened to connect or disconnect wires or terminals with circuits | Provide a secure mechanical connection, less prone to loosening, reducing the risk of electric shock or short circuits; tolerate relatively high currents, suitable for high-power circuits and devices | Complex installation and maintenance requiring tools for fixing or disassembling, not suitable for quick connections |

|

Pin terminal

|

Metal pin terminals that can be inserted into holes on circuit boards directly | Easy installation and disassembly; typically requires less physical space, suitable for compact applications | Not suitable for harsh environments and high-current applications; prone to deformation leading to improper insulation or short circuits |

|

Integral type

|

Metal push buttons that directly connect wires without any terminals | Provide waterproof protection for the switch and wires, and easy installation without sockets or holes on circuit boards or devices | May have limited compatibility with other devices and connectors, limited flexibility, and customization options |

From the comparison of advantages and disadvantages in the table, plug terminals demonstrate relatively good overall performance while tolerating high currents and being compatible with various devices. Screw terminals, pin terminals, and integral types should be chosen based on specific application needs, such as installation space and current requirements.

In summary, metal push button switches are common in electronic devices, mechanical systems, and control systems. They provide reliable operation and can be used in various environments. Clarifying requirements, and selecting the appropriate type and specifications ensures that metal push button switches reliably meet application conditions.

Metal push button switch manufacturer China

KANGERLE, a push button switch manufacturer located in Wenzhou, Zhejiang Province, has 30 years of industry experience. We have been specializing in the research, development, manufacturing, and sales of high-quality electronic switches. Currently, we offer multiple series of metal push button switches and indicators. Our range includes latching, momentary, LED illuminated types, waterproof (up to IP67), and protective (up to IK10) switches. Our products are widely used in household appliances, automotive industries, medical equipment, hotels, electronic devices, and more, gaining trust and recognition from customers. KANGERLE welcomes domestic and international visitors to our factory for guidance. For more details about switches, please visit the official KANGERLE website: https://www.kel-switch.com/!