In today’s power setups, safety, handling, and watching are vital. Smart circuit breakers sit at the heart of these tasks. Yet, strong detection switches play a big part in keeping those breakers running smooth. The series of detection switches brings sharp awareness and trust. It gives exact error spotting for smart circuit breakers. This lifts the whole system’s safety and steadiness a lot.

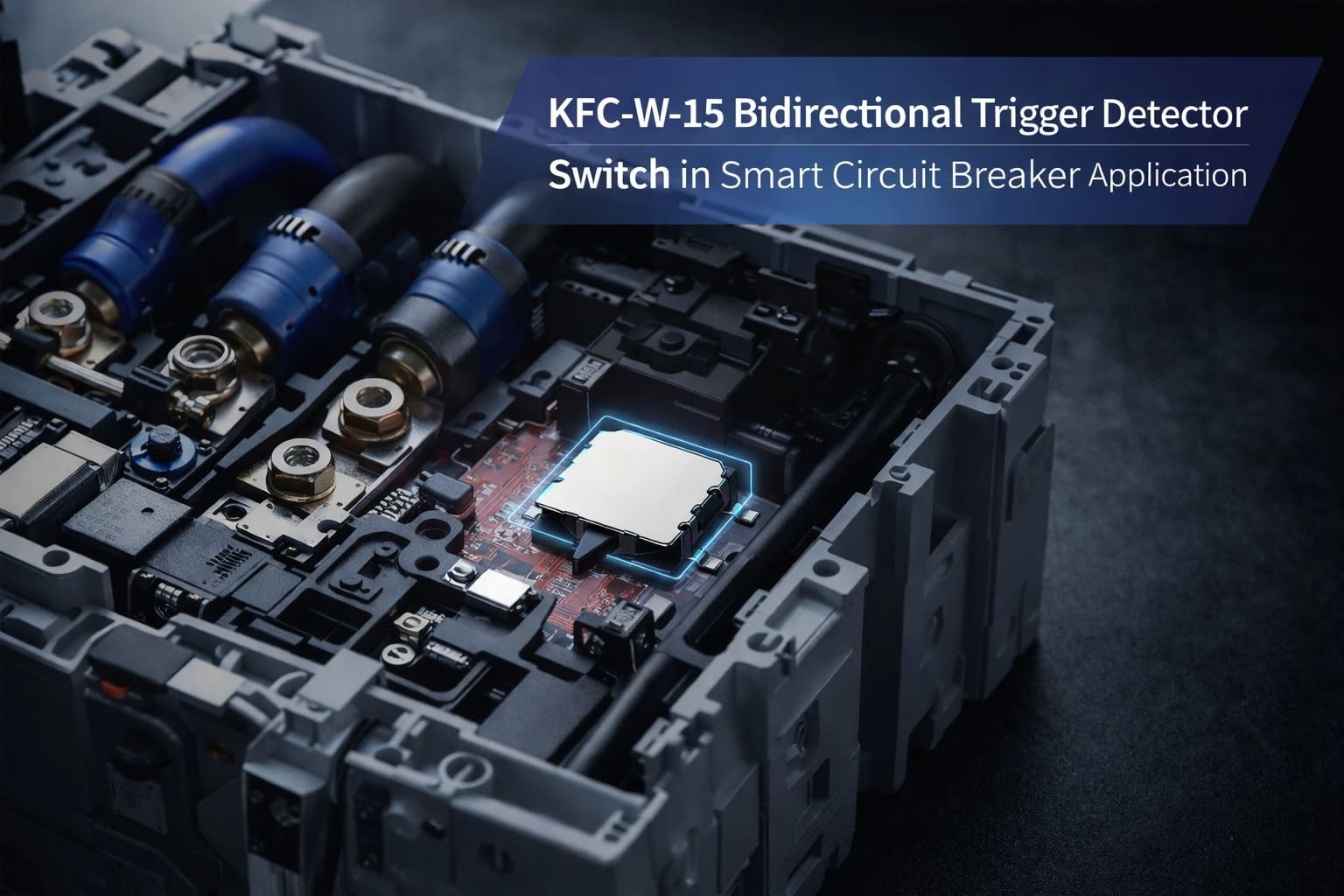

This piece talks about the job, main strengths, and common uses of the KFC-W-15 detection switch in smart circuit breakers. We start with basics and go into details.

What is a Smart Circuit Breaker?

Smart circuit breakers go beyond old ones that just turn on or off. They mix in talking, checking, and self-running features. These breakers watch things like flow, power level, and heat right away. If something odd shows up, they cut the line fast. They also send warnings to the control setup. This lets fixers deal with problems quick and cut down on stop times.

In factory tools, big structures, and key power lines, smart circuit breakers cut risks well. They lower money losses too. High-accuracy detection switches give a strong promise for their steady work. Without them, systems might miss small issues that turn big.

Introduction to the KFC-W-15 Detection Switch

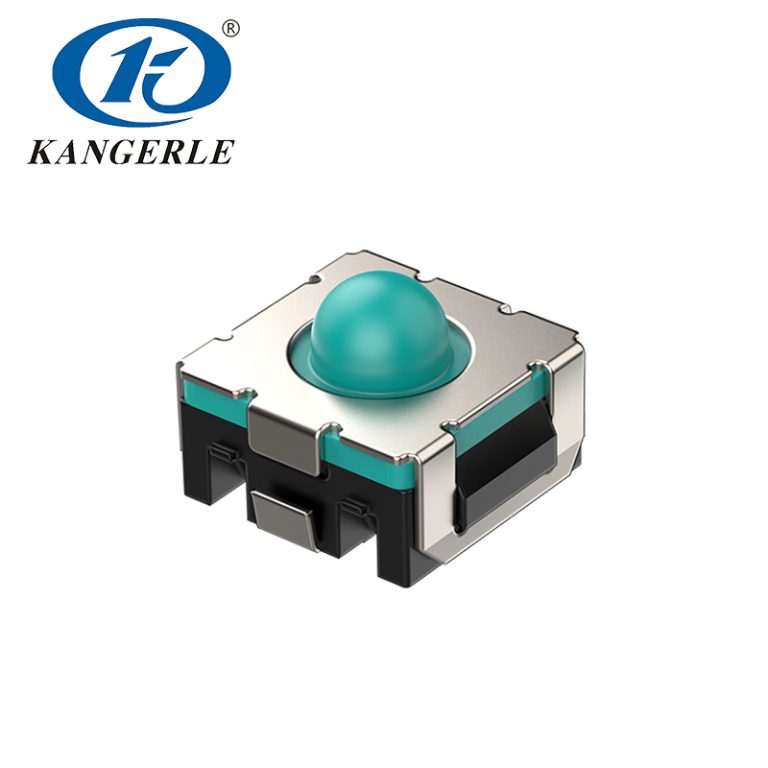

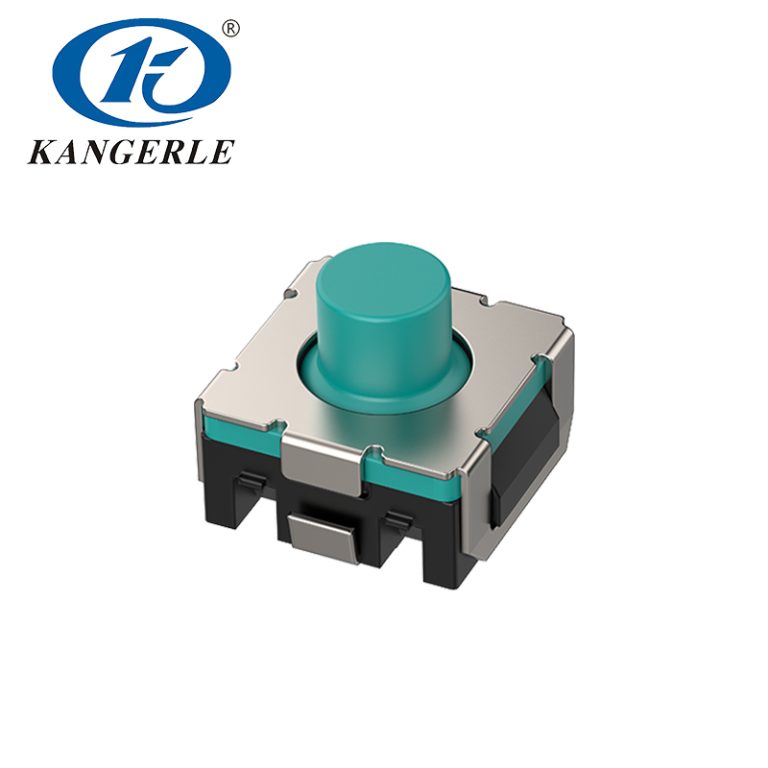

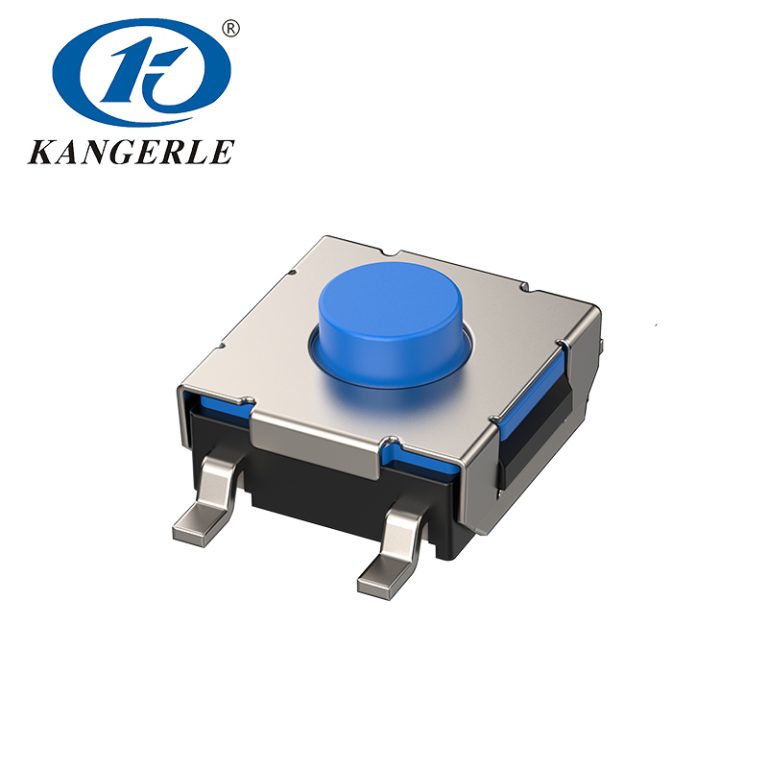

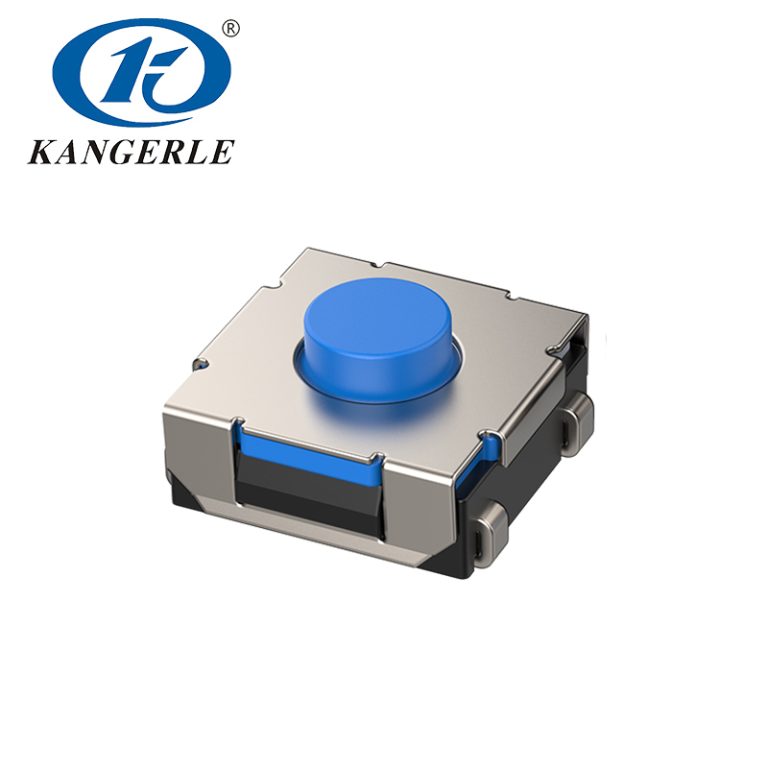

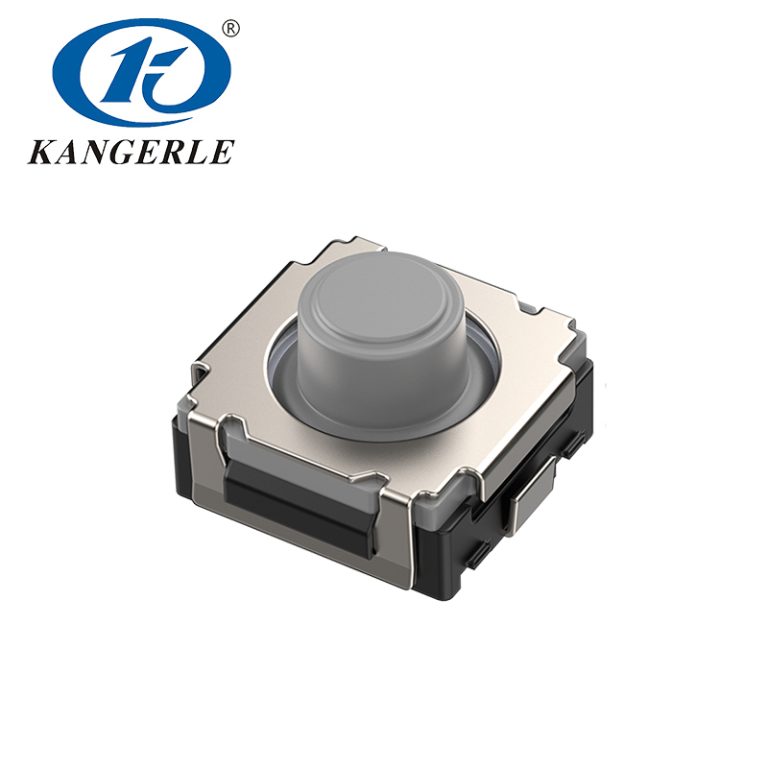

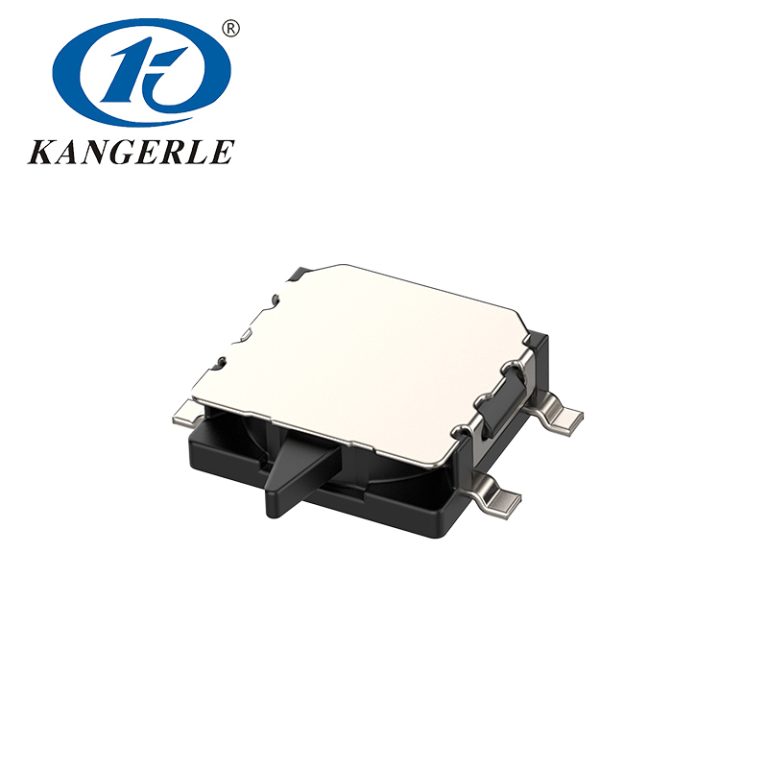

The KFC-W-15 detection switch stands as a sharp-feeling switch. It has a two-way start setup. This lets it answer right to outside machine moves from both sides. It offers steady and sure signal changes. The item shows off its tiny size, slim build, and tight form. This makes it great for tight spots in smart circuit breakers, power split units, and exact electric gear.

As a top-work, super-slim detection switch, the KFC-W-15 brings steady spotting skills in small setup areas. It boosts the safety, trust, and smart level of tools well. It fits for jobs that need high spotting rightness and quick answer, like factory self-run, home power setups, and power share lines. People pick it because it works in tough spots without failing.

Core Advantages of the KFC-W-15 Detection Switch

- Two-Way Start: It backs starts from both ways. This gives more bendy setup choices.

- Super-Slim, Tight Design: Slim and small, perfect for packed electric builds.

- Sharp Feeling Spotting: It picks up machine shift changes right and answers fast.

- Steady and Sure: Good for long-time, often use with even work levels.

- Simple Mix-In: Works with many smart circuit breakers and power handle setups.

These perks make it stand out from basic switches. For instance, the slim design saves space in crowded boxes.

Role of the KFC-W-15 Series in Smart Circuit Breakers

The series plays a key part in making breakers smarter. Let’s break it down.

1. Boosting Error Spotting Skills

Old circuit breakers often act only when errors get bad. But the series can spot odd shifts in flow and power level early on. This cuts risks like fires and tool harm well. In factory spots with often load shifts, early spotting matters a lot. It guards exact tools and keeps making going on. Think of it as an early warning bell.

2. Quick and Right Safety Answer

The series detection switch acts fast. It aids the breaker in cutting the bad line right when an error starts. This stops the issue from growing big. Such speed counts a ton in data hubs, plants, and power lines. No waiting means less damage.

- Backing Smart Ways and Far Watch

The series can pair with the talk setup of smart circuit breakers. It gives back real-time line status to the handle spot. This lets far watch, error warnings, and setup bettering. It matches the growth paths of Industry 4.0 and the Internet of Things (IoT). You can check from anywhere.

Application Value of the KFC-W-15 in Smart Circuit Breakers

In smart circuit breaker setups, the KFC-W-15 two-way detection switch gets used mostly for:

- Breaker machine spot checking

- On-off status give-back

- Machine move length spotting

- Safety lock-in and odd status knowing

With sharp-feeling spotting and quick answer, the KFC-W-15 aids smart circuit breakers in seeing odd states ahead. It lets more right safety handling and cuts error risks. This value shows in daily use.

Typical Application Scenarios

Places where this switch shines include various spots.

Industrial Automation Equipment: Fast spotting of overloads and short lines to keep making lines steady. Factories run better.

Smart Home and Residential Power Distribution: Guard home items and cut electric danger spots. Families stay safe.

Data Centers: Make sure power setups stay steady and stop server harm. Data keeps flowing.

New Energy Systems (Solar/Wind Power): Reach quick error spotting and safe power cut. Green power stays reliable.

In each case, it adds a layer of protection.

About Zhejiang Kangle Electronics Co., Ltd.

Started in 1993, Zhejiang Kangle Electronics Co., Ltd. focuses on study, growth, and making of detection switches, tiny switches, and other electric parts. The firm’s items get used a lot in factory tools, smart power setups, home items, data hubs, and new energy areas. It holds ISO9001 and IATF16949 marks. This means it gives sure and top-grade switch answers to buyers around the world.

Summary

The series detection switch shines with its sharp feeling, quick answer, and steady work. It turns into a must-have main part in smart circuit breakers. No matter in factory, house, data hub, or new energy setups, it boosts the safety, trust, and smart side of power lines well.

Picking the series means a sure promise for long-time steady run of electric setups.

Frequently Asked Questions (FAQ)

Q1: How does the KFC-W-15 series stand out from regular detection switches?

A: It backs two-way spotting. It has a super-slim size. It brings higher feeling, quicker answer speed, and more sure build plan. This lets it spot finer line odd bits.

Q2: Can it fit right into current smart circuit breakers?

A: Yes. The series works with many smart circuit breaker setups. Mixing in stays simple.

Q3: Does it fit for factory spots?

A: For sure. The item gets built for tough spots. It suits plants, data hubs, and like places.

Q4: How does it boost electric safety?

A: It spots errors early. It cuts lines quick. This stops mishaps from getting worse.

Q5: Can it cut fix costs?

A: Yes. Spotting issues early can lower big fixes and stop-time losses.