Metal push button switches show up in lots of gadgets folks handle daily. Think about big machines or kitchen tools. These parts take care of jobs that need steady control in rough spots. Builders and planners pick them for setups that face hard use. This post looks at what sets these switches apart. It talks about their build, jobs, and role in today’s gear.

The Core Design and How They Work

Every metal push button switch has a basic but tough setup. You push the button. It joins or splits an electric path. That sends a sign to begin, halt, or change something. The metal case, like from steel or light metal, guards the inside bits from harm. This cover fights rust and hits. That’s why you see them in damp or bumpy places.

Let’s dig into the build. The press part links to points inside. These touch or part to guide power. Springs make the button snap back after you let go. This stops random starts. Power levels differ by use. Some deal with weak signs at 12V DC and 50mA. Others take bigger loads up to 250V AC. Heat ranges often go from -10°C to 60°C. So they fit in cool rooms or warm boards. Barrier strength tops 100MΩ. It keeps signs clear with no slips.

These facts matter in real jobs. Take a plant line. A metal push button switch might start belts. Dust and shakes test it each day. Touch drag stays under 500mΩ for good flow. Hold voltage hits 100VAC or more to skip shorts in jumps.

Key Materials Used in Construction

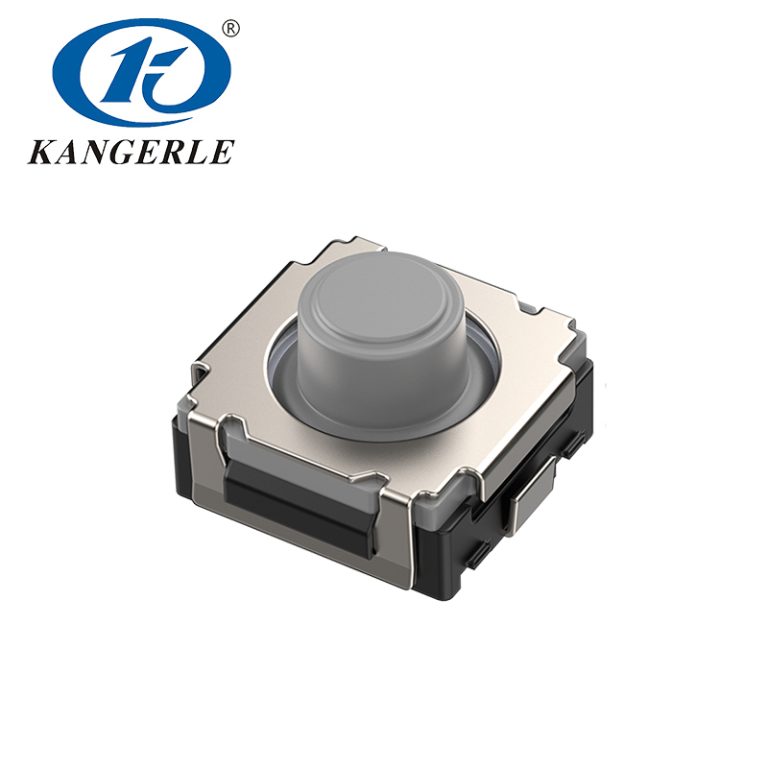

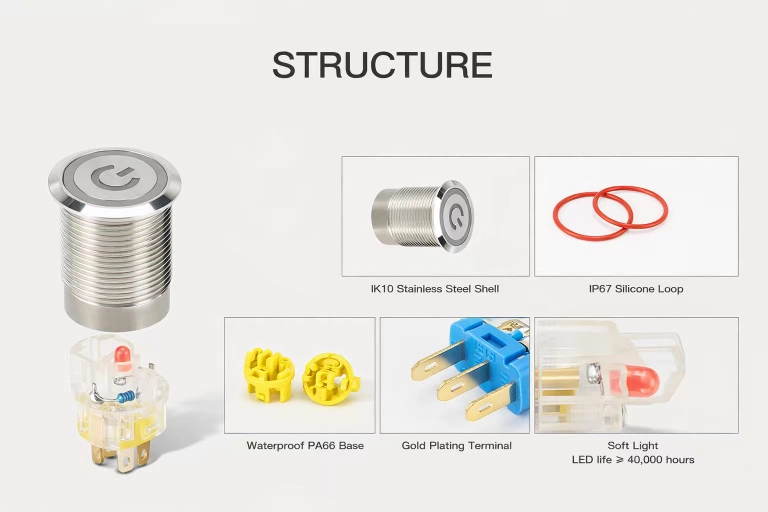

Stuff in a metal push button switch sets how well it runs. Steel leads for its power against rust and marks. It works great for outside stands or boat gear. Other mixes like brass pop up in easy spots. They give fair price and strength. Rings around the button, from rubber, raise guard levels to IP67. That blocks dust full and lasts under water a meter deep for 30 minutes.

This pick of strong stuff links to work needs. In car boards, drivers hit buttons many times. The machine life can reach 100,000 turns or more. Power life matches, often at 10,000 under full weight. Marks like UL, TUV, CE, CB, and RoHS show these switches hit safety rules. They cut risks in world sales.

Common Circuit Configurations

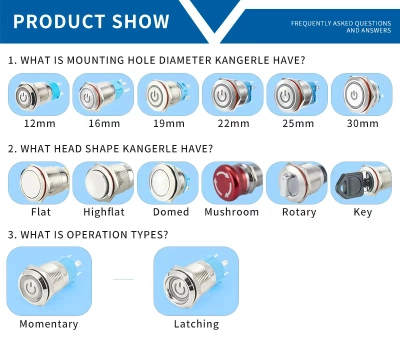

Paths in metal push button switches have picks like open at rest (NO) or shut at rest (NC). In open setup, the path joins only on push. It fits start keys on tools. Shut versions split on push, good for quick stops in lifts. Some give single-pole switch (SPDT) for flip between two ways, like changing lights in rooms.

These setups fit exact wants. Push strength, in grams (gf), goes from 50gf for soft taps to 200gf for firm ones. Users feel the move without hurt.

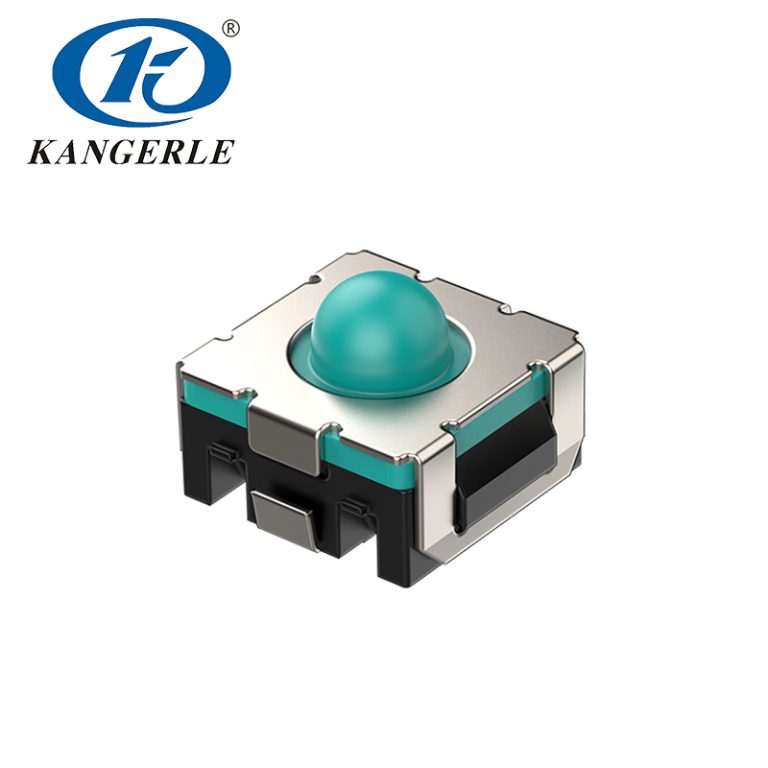

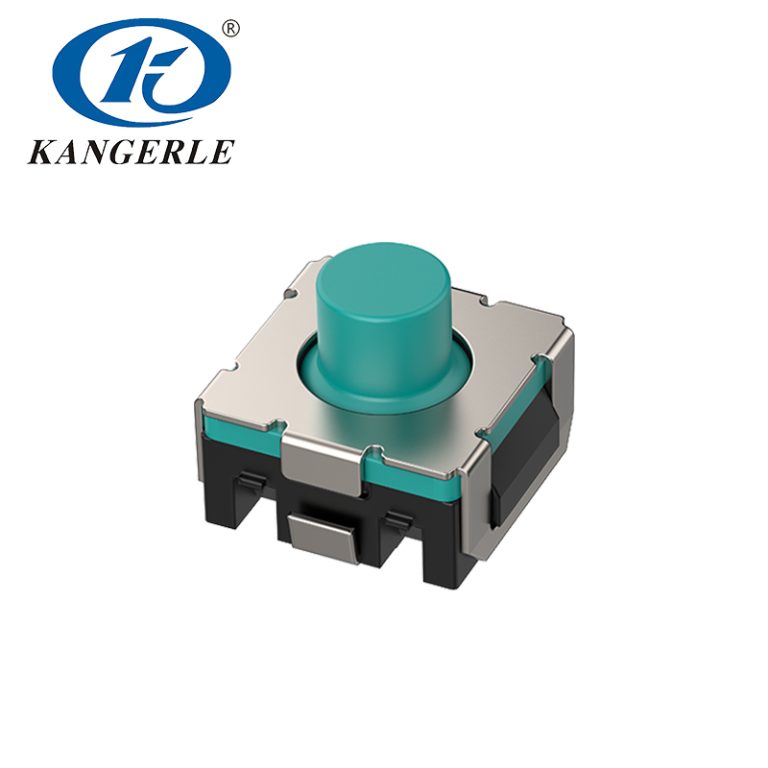

Variations to Suit Different Needs

Metal push button switches have types that fix special problems. They spread across fields. Water-tight kinds block liquids. They stay common in wet plants like food spots. Light-up ones add LEDs for sight in dark areas, like late shifts or car insides. Tough-against-harm models have strong cases to beat breaks, seen in street sellers.

Each type grows from the main build. A water-tight metal push button switch might use rings and fill to get high block. Light-up metal push button switches mix LEDs that use little power, under 20mA. They show shades like red for alerts or green for ok. Steel metal push button switches stress long run, with faces that fight prints and stuff.

The pick hangs on the place. In health tools, where clean matters, flat metal lets quick wipes. Plant controls gain from hit-proof, lasting falls or bumps without stop.

Momentary vs. Latching Actions

Short action means the switch works only while held, then resets. It suits rings or door opens. Lock action stays till pushed again, like on/off in sound boxes. This split changes how folks use it. Short stops wrong long runs. Lock saves work in steady jobs.

True uses show the gap. A short metal push button switch in a lift truck sound blasts quick, skips endless noise. Lock ones in light boards hold paths firm till hand change.

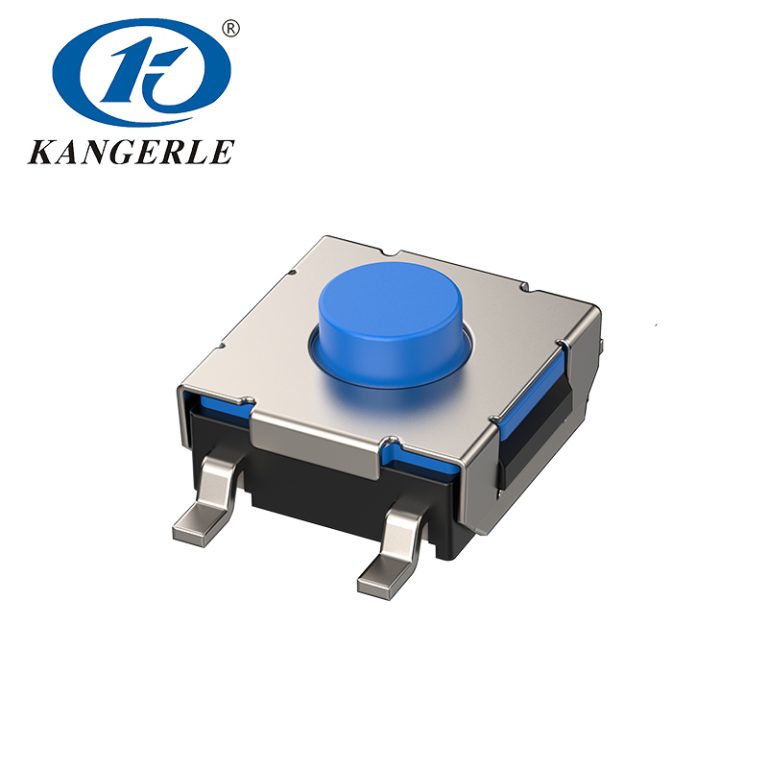

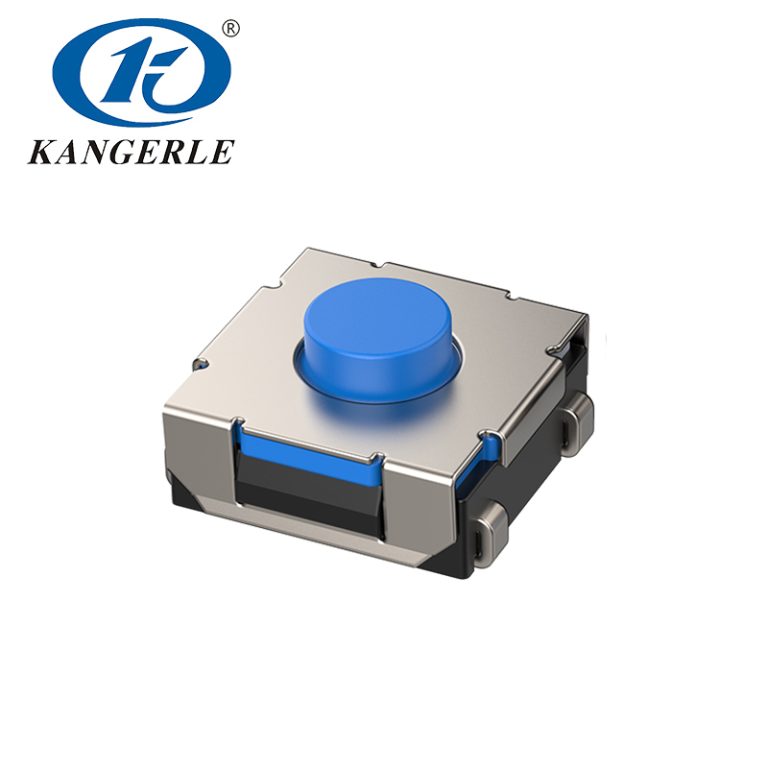

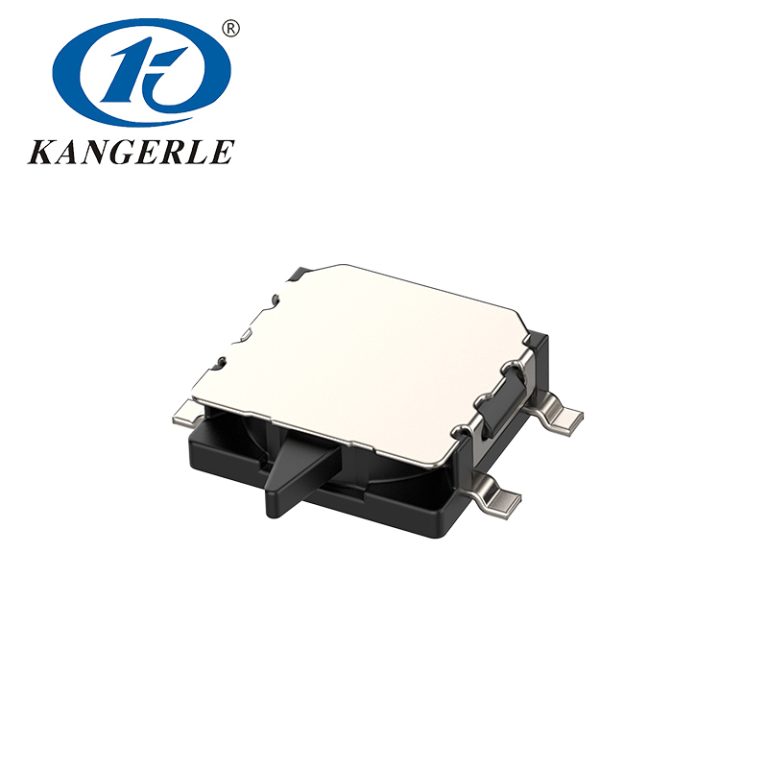

Size and Mounting Options

Sizes change to slip in tight or big spots. Board-fit kinds screw in holes, lock with nuts for shaky places like trucks. Level-fit sit even with faces for clean looks in home items. Screw bodies make sure tight holds, with widths from tiny to wide for different board thick.

Fit way affects trust. In bad outside, like road signs, firm holds stop loose over time. They keep touch good.

Where These Switches Make an Impact

From plants to rides, metal push button switches fit into setups that want exact and strong. In machine work, they guide motors and gates, take turns in millions without break. Car jobs include dash keys, where they last heat, chill, and steady pokes from riders.

Health gear counts on them for clean, sure run in things like drip pumps. Guard systems use harm-proof metal push button switches for entry boards. They fight break tries. Talk tools, like waves, gain from water-proof builds that run in wet or dirt.

Counts prove their worth. Month make in top spots tops 50 million bits, fills world need. In home tech, they show in tools like heat boxes, give feel back that folks trust.

Role in Enhancing Safety

Safe traits shine in these switches. Quick stop keys, often big and red, use lock ways to halt fast. High power marks stop sparks, and barriers keep folks safe from zaps. In lifts, they start calls or lights, with marks that fit rules.

Such jobs grow trust. Workers in stuff plants push these, know they hold in fumes or spills.

Boosting Efficiency in Operations

Good run comes from fast answer and low fix. Light push strength cuts tire for folks who hit keys lots. Long turn counts mean less swaps, drops stop time in make lines. Light features speed find in busy boards, makes work smooth.

In store houses, switches on sort tools start belts right, handle packs by thousands daily without snag.

Benefits That Set Them Apart

Next to plastic kinds, metal push button switches give better last. They fight wild heats, from cold winters to hot days, without split. Rust fight grows life in wet or salt air, like shore sets.

Save money shows over time. First buy pays with machine lives up to 1,000,000 turns, cuts fix wants. Power save in light models keeps draw low, helps battery gear.

Green plus include RoHS fit, skips bad stuff. Metal you can reuse backs green make ways.

Durability in Harsh Environments

Rough spots test switches each day. Water-proof metal push button switches block water blasts, as in car cleans. Harm-proof types take hits up to some power, guards insides.

IP67 levels prove dust-tight and water-hold, shown by hard checks.

Customization for Specific Projects

Change lets fit to wants. Picks for shades, marks, or light sets match name. ODM/OEM help firms change builds, mix smooth into goods.

This bend helps in special fields, like sky boards where weight and size rules want right fits.

Selecting and Maintaining for Long-Term Use

Pick means match facts to needs. Look at load mark. Make sure it takes the path’s power and flow. Guard level counts for open. IP67 fits outside. Push strength should feel ok for folks, skips too hard or loose.

Keep up holds them going. Steady clean takes off dirt, special around rings. Check for wear after lots turns, swap if points bad. Right set skips pull on lines, stops faults.

Tools like testers check flow, catch problems early.

Factors to Consider Before Purchase

- Voltage and Current Ratings: Fit to setup wants to skip over.

- Environmental Protection: Bigger IP for wet or dust.

- Life Cycle Expectations: Pick counts over guess use.

- Certifications: Seek UL, TUV, or CE for rules.

- Mounting Style: Make sure works with board plan.

These moves guide picks, lead to sure mixes.

Step-by-Step Installation Guide

Begin with hole drill to size. Put in the switch, lock with nuts. Join lines to ends, use squeezes for strong holds. Check path before full put. For water kinds, put seal on edges.

This way, when done, gives steady run from start.

Introducing Zhejiang Kangerle Electronics Co., Ltd.

Zhejiang Kangerle Electronics Co., Ltd. sits in Wenzhou since 1993. It acts as a sure giver of metal push button switches. The firm makes these parts plus tiny switches and find switches. It helps fields like cars, guards, and talks. With a plant about 20,000 square meters, it keeps high ways via ISO9001:2015 and IATF16949:2016 marks. Goods have ok from UL, TUV, CE, CB, CQC, and RoHS, shows care for good. Month out tops 50 million bits, backed by new tools and a group of over 20 builders, 50 fix folks, and 40 bosses. Sellers in Shenzhen, Hangzhou, and Wenzhou deal spread, while ODM/OEM give change picks. This build makes the firm a steady mate for last, strong switches.

Conclusion

Metal push button switches bring the power and trust needed in hard jobs, from plant keys to daily tools. Their build looks at long run and safe. They make a wise pick for works where break can’t happen. Know their traits and pick smart. Folks can boost setup run and drop long costs. As tech grows, these switches change too. They meet fresh tests straight.

FAQs

What makes a waterproof metal push button switch suitable for outdoor use?

A waterproof metal push button switch has rings and cases that stop wet and dirt. Often marked IP67. This lets it run in rain or damp without short. Common in yard tools or boat boards. The metal part adds fight to rust. It grows use time in open spots.

How does an illuminated metal push button switch improve user experience in low-light environments?

An illuminated metal push button switch has in LEDs that bright the key. Makes it simple to find and use in dim places like car seats or night plants. The shine gives see back on state. Cuts mistakes. And takes small power to skip battery drain.

What are the key advantages of a stainless steel metal push button switch over plastic ones?

Stainless steel metal push button switches give better last against hits and stuff. With higher turn counts over 100,000 pushes. They fight rust and keep look longer. Good for busy spots. While plastic might split under push or dull over time.

Can a vandal-resistant metal push button switch withstand heavy impacts?

Yes. A vandal-resistant metal push button switch uses strong metal and firm fit to take meant force or random bumps. This build guards insides in open places like money machines or ride stops. Keeps run steady even after hard touch.

How do certifications impact the choice of a metal push button switch?

Marks like UL, TUV, and CE check that a metal push button switch hits safe and run rules. Key for fit in world sales. They ok things like barrier and hold power. Give buyers trust in steady for big jobs.