In labs, machines like centrifuges and incubators need to work with great care. These tools are key for science studies, medical checks, and factory tasks. They must run smoothly and last long. Metal push button switches help a lot here. Companies like Zhejiang Kangerle Electronics Co., Ltd. make these switches. They ensure labs can control devices well. This article looks at how these switches help centrifuges and incubators. It shows why they matter for exact control and smooth running.

Why Precision Matters in Lab Tools

Lab equipment faces tough conditions. Even small mistakes can ruin experiments. Centrifuges spin fast to split samples by weight. They need exact speed and time settings. Incubators keep the right heat and wetness for growing cells or germs. Any error can waste materials or cause danger. This makes strong control parts vital. Metal push button switches fit this need. They last long, give clear feedback, and handle rough settings.

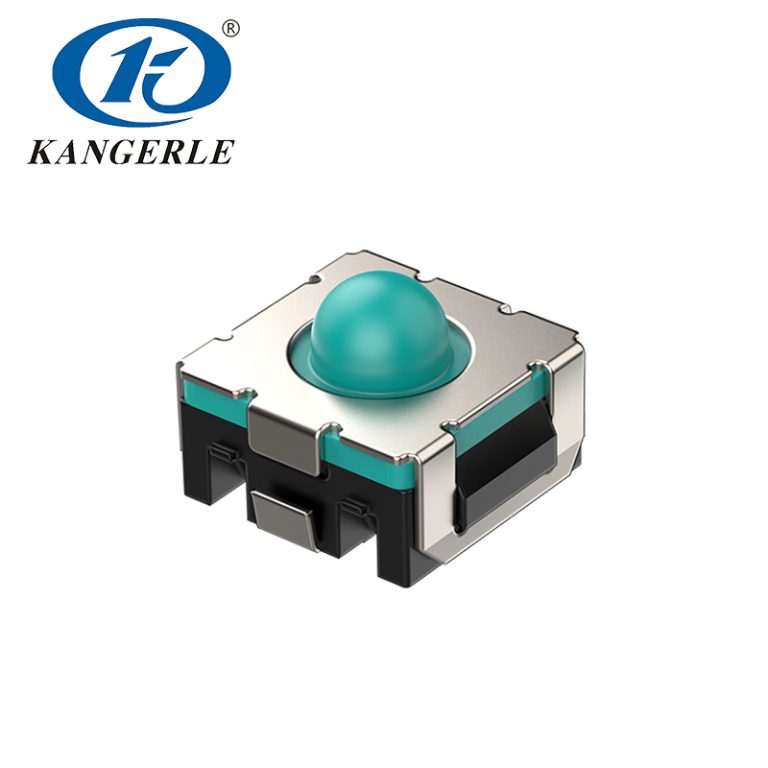

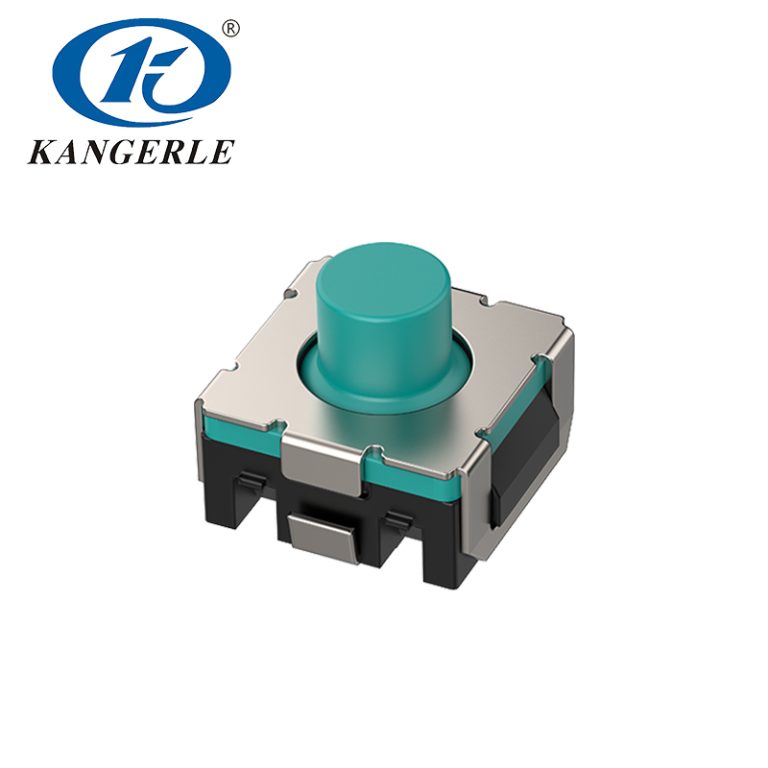

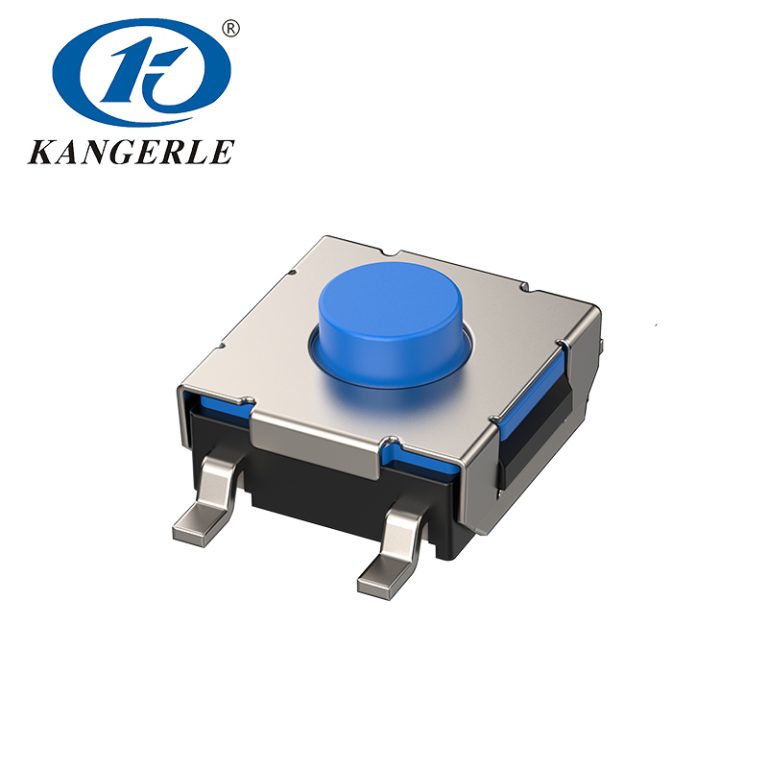

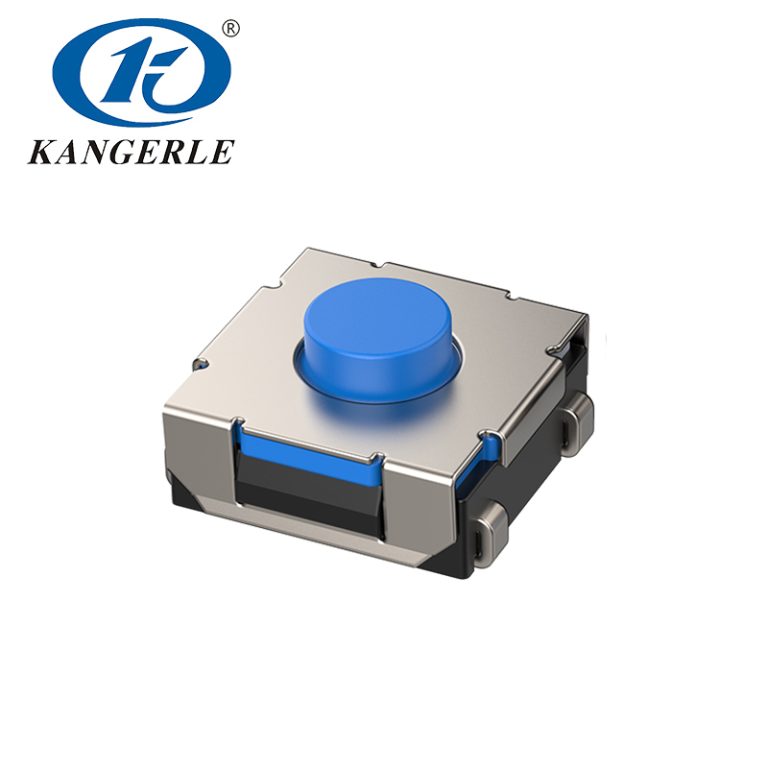

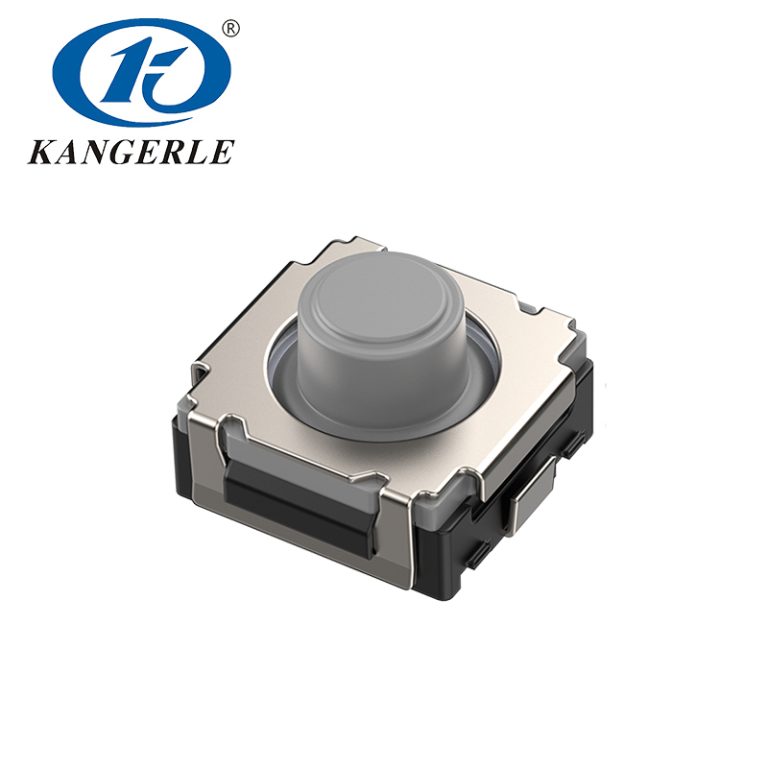

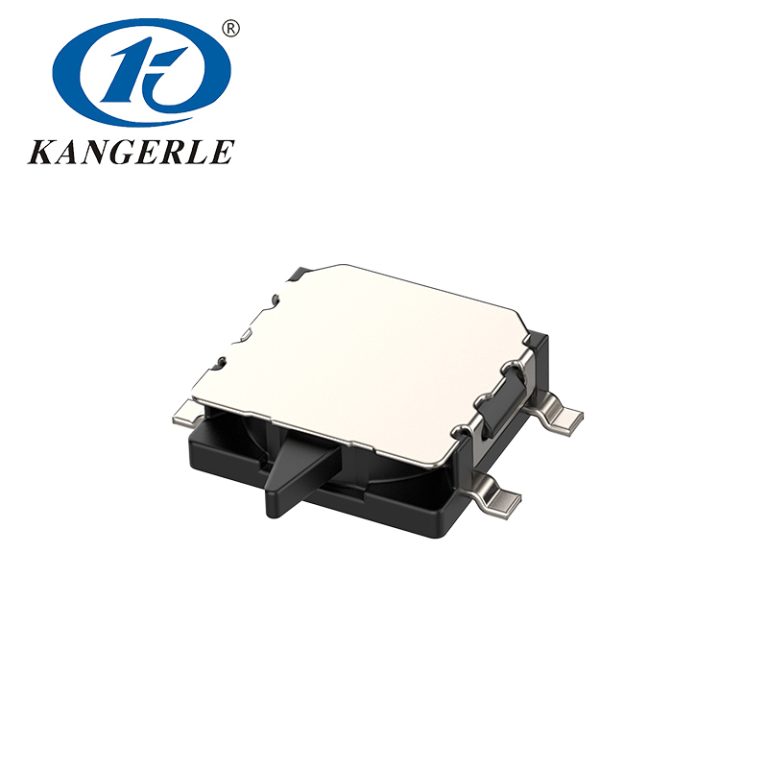

What Are Metal Push Button Switches?

Metal push button switches are simple devices. They turn electric circuits on or off to run machines. Unlike plastic ones, they use steel or aluminum. This makes them tough and safe from rust or heat changes. They have set push strength, low resistance, and good insulation. These features suit lab work well.

How They Work in Centrifuges

Centrifuges use metal push button switches in important ways:

Start and Stop: These switches start and stop the machine. Operators set exact speeds. They can stop it safely too. The feel of the switch confirms it works. This avoids looking away.

Speed and Time: Many centrifuges let you program settings with buttons.

Emergency Stop: Safety comes first. These switches stop the machine fast if something goes wrong. Their strong build ensures they work under pressure.

How They Work in Incubators

Incubators also rely on these switches:

Heat and Wetness Control: Buttons set the right temperature, like 37°C for cells. The switches last through many uses.

On/Off Power: The main switch is often metal. It turns the incubator on or off reliably. This keeps things clean with less touch.

Alerts and Safety: Alarms warn if heat or wetness changes. Switches with high insulation (100MΩ) send alerts without mix-ups.

Benefits for Lab Use

Metal push button switches have clear advantages:

Toughness: They handle repeated use and harsh conditions.

Accuracy: Low resistance and good insulation send signals well. This fine-tunes settings.

Safety: They protect against dust or water. This lowers failure risks.

Long Life: Some metal push button switches, last over 500,000 cycles. This cuts repair needs in busy labs.

Mixing with New Lab Tech

New centrifuges and incubators use digital screens. But buttons stay important for emergencies. Metal switches act as a backup. Some metal push button switches have a SPDT setup. This lets operators switch modes easily.

The push strength, feels right. It reduces tiredness during long work. This helps researchers a lot.

Keeping Them Working

To make switches last, check them often. Clean off dust or dirt. Look for wear on the metal. Ensure wires are fine. Some metal push button switches can work for years with 1,000,000 cycles if cared for.

About Zhejiang Kangerle Electronics Co., Ltd.

Zhejiang Kangerle Electronics Co., Ltd. started in Wenzhou in the 1990s. It leads in making electronic parts for homes, security, video, communication, cars, and computers. For over 30 years, it has focused on micro switches, detector switches, and push button switches. The company has over 20 engineers, 50 technicists, and 40 senior managers. It earned the STAR ENTERPRISE title from the local government. It passed ISO9001:2015 and IATF16949: STREAMlined standards. With top equipment and skills, it makes over 50 million switches monthly.

Kangerle warmly welcomes customers from both domestic and international markets to partner with them for a brighter future. By fostering these relationships, the company aims to continue its legacy of excellence and contribute to the advancement of future technology.

With its solid foundation and forward-thinking vision, Zhejiang Kangerle Electronics Co., Ltd. is well-positioned to lead the industry for many years to come.

Final Thoughts

Metal push button switches are crucial for centrifuges and incubators. They bring toughness, safety, and fit with new tech. Labs can trust them for steady results. As precision grows, these switches will keep playing a big role.

Common Questions

Why choose metal over plastic switches in laboratory settings?

Metal switches offer superior durability, corrosion resistance, and longer service life compared to plastic alternatives. They are specifically designed to withstand demanding lab environments, including exposure to chemicals, moisture, frequent sterilization, and mechanical stress. Their robust construction ensures reliable performance and enhanced safety in critical applications.

How can I determine whether a switch is compatible with my centrifuge equipment?

To ensure compatibility, evaluate key technical specifications such as voltage and current ratings, actuation force, ingress protection (IP) rating, and mounting dimensions. It’s also important to consider environmental factors like temperature range and chemical exposure. Consulting with a knowledgeable supplier or manufacturer can provide tailored recommendations based on your equipment’s requirements.

What maintenance do these switches require?

Regular maintenance is essential for optimal performance. This includes periodic cleaning with appropriate solvents, inspection for signs of wear or damage, and ensuring electrical connections remain secure. Proactive checks help prevent failures and extend the switch’s lifespan, especially in high-use or harsh laboratory conditions.

Where can I find high-quality switches suitable for laboratory use?

Reputable suppliers such as Zhejiang Kangerle Electronics specialize in manufacturing switches that meet rigorous safety and performance standards for laboratory and medical equipment. Their products often feature certifications like IP67 for dust and moisture resistance, and are designed to comply with industry-specific requirements for reliability and user safety.