Have you ever walked into an elevator and hit a button to get to your floor? Those little, strong buttons help make the trip safe and easy. Metal push button switches stand out because they work well in places with lots of use. This post looks at how these switches fit into elevators, why they count, and what makes them a good pick for folks who own or design buildings. If you deal with elevator setups or just want to know about the stuff behind daily rides, keep reading. We will go over the simple facts, real examples, and ways to keep everything going smooth.

Understanding Metal Push Button Switches

These switches look basic. But they do a lot in terms of how they work and how they are made.

What Are Metal Push Button Switches?

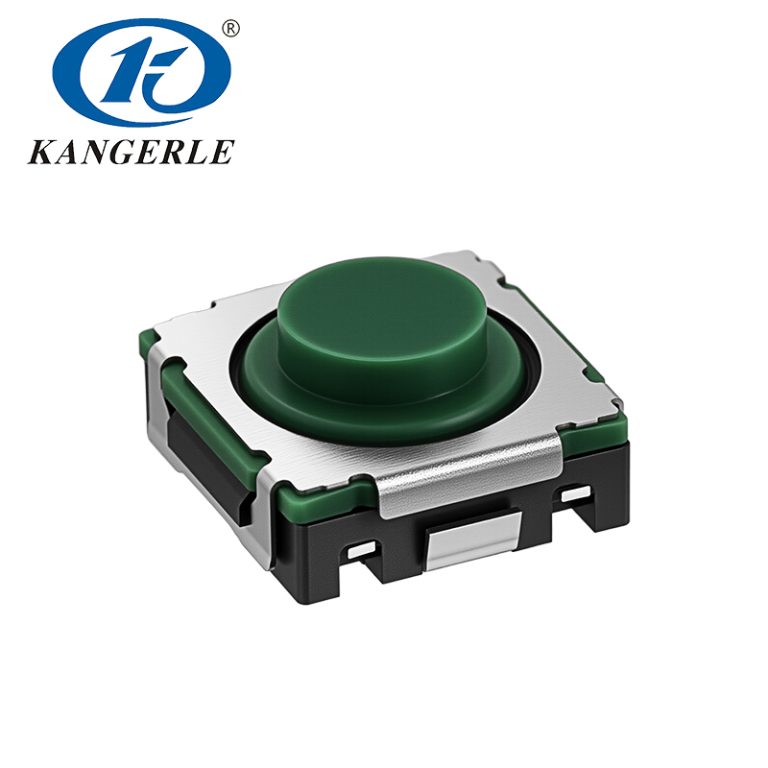

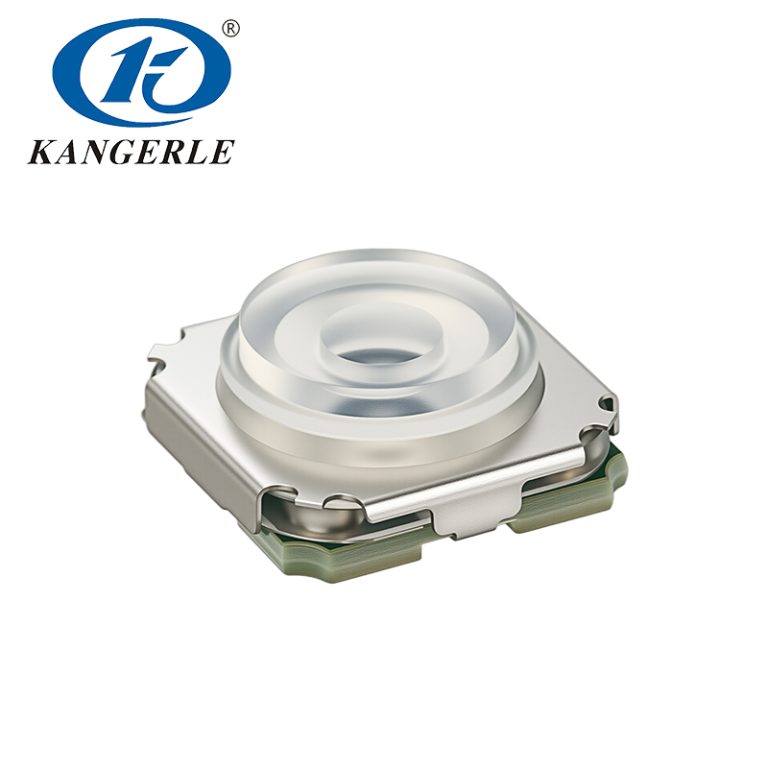

In simple terms, metal push button switches are tools that connect or break an electric path when you push them. They come from hard metals like stainless steel or aluminum. And they take lots of presses without breaking down quick. In elevators, they link to control boards. They send signs to move the car up or down.

Picture this. You push a button, and it glows or makes a sound. That move starts a reply in the elevator’s main system—the control part. Without good switches, trips might feel rough or not steady. Metal kinds do well here. They fight off marks, bumps, and rust better than plastic types.

Key Features of These Switches

What makes them different? Let’s list them out.

- Strength: Made to hold up through tons of pushes. In crowded spots, that’s key.

- Weather Proofing: Many have covers to stop dirt, water, or damp air—great for elevators in any weather.

- Light Options: Often come with LED bulbs for easy seeing in dark halls or when power drops.

- Feel Feedback: A nice snap or touch when pushed, so users know it worked.

These traits make them easy to use. For example, in a hospital lift, bright lights and firm make ensure fast, no-mistake use in urgent times.

Applications of Metal Push Button Switches in Elevators

Elevators count on these switches for things like simple floor picks to safety stuff. Here’s how they play a part.

Floor Selection and Call Buttons

Inside the car, metal push button switches let riders choose floors. They sit in a row on the board, each linked to one level.

Why metal? Lots of traffic. In tall work buildings, many folks might hit the same button each day. Metal stays strong. It keeps the board neat for years. Also, they work fine with raised dots for blind folks, helping those who can’t see well.

In new buildings, these switches connect to smart controls. Push one, and it talks to the elevator’s program to plan paths—grouping stops to cut time. This way saves wait and power. For fix-up teams, it’s good too. Bad switches show in checks, so less stop time.

Outside the car, floor call buttons use like metal switches. They call the lift, often with up or down marks. In wet places, their block on damp stops breaks or fails.

Emergency and Specialized Functions

Not only for floors. Metal push button switches deal with bells, door waits, and fire modes.

Look at the stop button. It’s a big, red one that stops the car right away. Metal build makes sure it works even if hit hard. In load lifts, where stuff is heavy, these switches run special modes for work.

Rules for safety need strong parts. Metal switches fit codes for fire hold and hit strength. When power goes out, lit ones guide folks to help calls. This steady work builds faith—riders feel safe knowing buttons won’t quit when needed.

Why Metal Push Button Switches Excel in Elevator Design

Picking metal isn’t by chance. It helps how things run and look.

Strength and Longevity Compared to Alternatives

Plastic buttons break or lose color over time. Metal? It stays firm against bad acts or random hits. In open spots like shops, this means less swaps, which saves cash.

Think about how long they last. Some metal switches take over a million pushes. That’s years without trouble. For those who run buildings, it means less fix costs and pleased renters.

Aesthetic and Branding Benefits

Looks are big. Shiny metal gives lifts a nice feel, which lifts the building’s name.

In fresh builds, switches mix with steel doors or glass sides. This match makes the ride better, so it feels high-end. For planners, it’s about making a smooth space where tech backs up looks.

Installation and Maintenance Tips for Metal Push Button Switches in Elevators

Doing it right from the start helps a lot.

Step-by-Step Installation Guide

Begin with a plan. Draw the board setup for easy reach.

- Look at fit: Make sure switches match the lift’s power and path type.

- Fix them tight: Use no-shake parts to deal with the car’s moves.

- Hook wires with care: Stick to color signs to skip shorts.

Check well after set up. Act like heavy use to find weak spots soon.

Common Maintenance Practices

Keep them clean. Dirt pile can make buttons stick. Wipe with soft cleaners each week.

Look for wear. Loose links? Pull them tight. In wet spots, check covers each year.

Button not glowing? Might be a loose bulb. No answer? Check the path. Fast fixes like this stop big woes. For experts, regular looks stretch life.

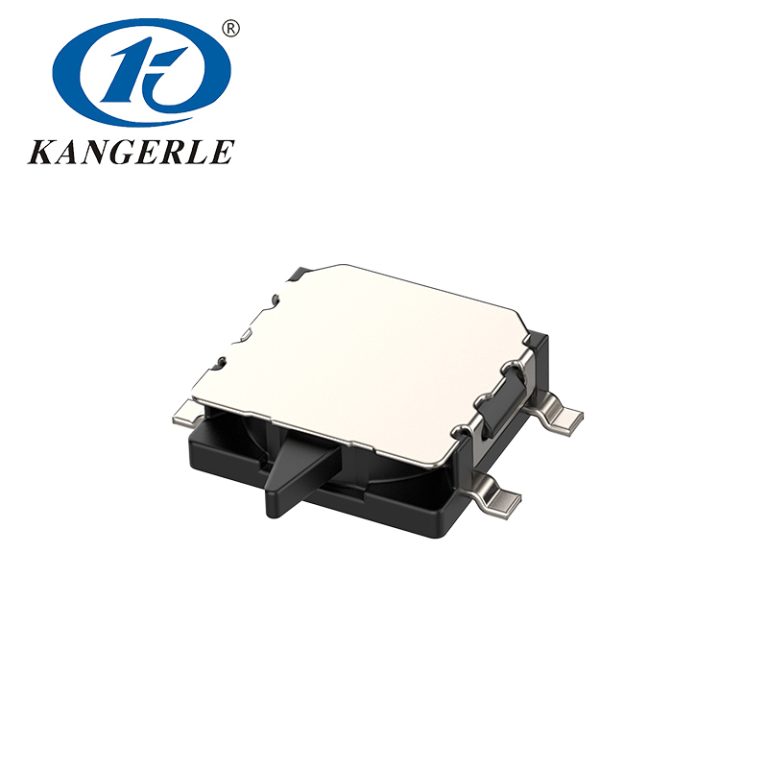

Company Spotlight: Zhejiang Kangerle Electronics Co., Ltd.

As a known maker of metal push button switches, Zhejiang Kangerle Electronics Co., Ltd. has made good parts since the early 1990s. Set in Wenzhou, China, the firm works on switches for home stuff, cars, and more. With marks like UL, TUV, CE, CB, and RoHS, they give steady goods backed by new ways and a good crew. Their month make tops 50 million bits, helping world spots with a focus on good make and buyer wants. For lifts or other uses, they bring strong answers that last.

Conclusion

Metal push button switches add power, safety, and nice looks to elevators. They make everyday trips steady. From full halls to stop calls, they take the load with no fuss. Picking right ones helps building run better and folks happy. As stuff gets new, these switches will stay big in safe, easy up-down moves.

FAQs

What are the main advantages of using metal push button switches in elevators?

Metal push button switches give great strength. They fight wear from steady use. They also guard better against wet and hits. This makes them fine for busy elevators. And their clean look helps the whole setup.

How do metal push button switches improve safety when used in elevators?

These switches make sure things work in bad times, like bell starts or door waits. Their firm make stops breaks. They fit safety rules and let riders feel calm.

Can metal push button switches be customized for specific elevator designs?

Yes, lots of makers let you change them, like add lights or marks. This lets switches fit the lift’s style. It helps both work and looks.

What maintenance do metal push button switches need when used in elevators?

Clean them often to keep them quick. Look at links and covers now and then to skip woes. With good care, they go years with no big fixes.

Why choose metal over plastic push button switches for elevators?

Metal types last longer in hard spots. They take more pushes and fight harm. This brings less stops and low costs in the long run.