Rocker switches are key parts in carbon monoxide (CO) detectors. They make these safety tools reliable and simple to use. Their strong build allows steady power control, smooth connection with sensor circuits, and lasting toughness in different settings. As a main control point, rocker switches help cut down false alarms. They also meet strict safety rules. This piece looks at how precise building and smart material choices improve CO detector work. This makes rocker switches essential for saving lives.

What Job Does the Rocker Switch Do in Carbon Monoxide Detectors?

Carbon monoxide detectors are vital safety tools. They warn people about CO gas. This gas has no color or smell. It can kill. Inside these systems, rocker switches are crucial parts. They handle power control and system start-up well. Putting them into CO detectors makes operation easy for users. It also keeps performance steady under changing conditions.

Key Jobs in Detection Tools

Rocker switches act as main control points in many electronic devices. Carbon monoxide detectors are among them. Their simple design lets users switch ON and OFF easily with a quick press. A rocker switch is also named a boat switch. Its button looks like a small boat shape. This comfy shape makes it easier to use. This matters most in emergencies when fast action is critical.

In CO detectors, the rocker switch controls the main power. It decides if the device is watching actively or waiting. Its basic mechanical action lowers user mistakes. It gives clear feedback through touch feeling.

Helping with Power Control and Steady Work

Stable power is essential for constant gas watching. Rocker switches help by handling large current loads. They have strong terminal setups. They take heavy current loads and come with varied terminal types. This keeps the detector powered without breaks. It works even when voltage changes or loads shift suddenly.

Also, lit rocker switches show device status visually. This makes operation clearer. For battery-powered units, smart power control via rocker switches saves energy. Users can turn off the unit when not required.

Connecting with Sensor Circuits for Better Results

Rocker switches join smoothly with sensor circuits. This allows real-time starting or stopping of sensing parts. It doesn’t harm calibration or memory jobs. Their role is bigger than simple switching. They act as steady links between human action and electronic responses inside the detector.

The rocker switch’s simple design and easy use make it common in many uses. For CO detectors, this means less chance of accidental shut-off. It also builds user trust during operation.

ZHEJIANG KANGERLE ELECTRONICS CO. LTD meets these needs. They offer rocker switches with different terminal types. The KCD3-11L series of rocker switches take heavy currents and have user-friendly shapes. This ensures smooth fitting into carbon monoxide detection systems. It also improves ease of use and trustworthiness.

How Does Rocker Switch Shape Affect Long-Lasting Trustworthiness?

Rocker switches must work the same way for a long time. They cannot lose contact quality or weaken physically. Their shape directly affects how well they handle repeated use in varied settings.

Physical Toughness and Contact Resistance

Long life depends on how a switch handles physical stress over years. Top rocker switches keep contact resistance low. They use exactly made contact materials and spring systems. These keep the best pressure during each switch action.

Their contacts come in single-pole single-throw and double-pole double-throw forms. This allows setups made for exact needs. Each type aims to lower sparking and wear during switching.

Effect of Material Choice on Long Life

Choosing materials is vital for lasting trustworthiness. Heat-proof plastics, rust-free metals for terminals, and silver alloy contacts are often used. These stop oxidation and heat damage. This is very important in homes. Devices there should last 5–10 years without failing.

KANGERLE’s products show this focus on material strength. The KCD3-11L series of rocker switches provide normal type, waterproof type, and lit type rocker switches. All are built to last in many uses. This includes factory tools and home devices.

Cutting False Alarms with Steady Switching

False alarms can break user trust in carbon monoxide detectors. A steady switching system stops power cuts or noise from shaky contacts. This avoids harming sensor tuning or causing wrong alerts. Rocker switches with clear action feedback lower accidental switching. This might happen from shaking or rough handling.

ZHEJIANG KANGERLE ELECTRONICS CO. LTD ensures lasting trust through careful material choice. The KCD3-11L series of rocker switches use exact contact building and strong case shapes. Together, these reduce the need for fixes. They also make detectors more believable over time.

Why Is Exact Building Vital in Rocker Switch Making?

Exact building guarantees each switch works the same within set electrical limits. This is a must for life-saving tools like carbon monoxide detectors.

Tolerance Control for Steady Electrical Work

Strict tolerance control during making keeps resistance levels the same across all switches. This steadiness stops differences that could cause overheating. It also prevents signal problems when joined with sensitive sensor circuits in CO detectors.

Exactly shaped cases also line up inner parts like springs, contacts, and movers well. This lowers physical wear over years.

Importance of Action Force Setting

Set action force gives expected touch feedback. It also stops accidental start or stop from small pressure changes. Think vibrations. For safety devices near HVAC units or moving doors, this matters a lot.

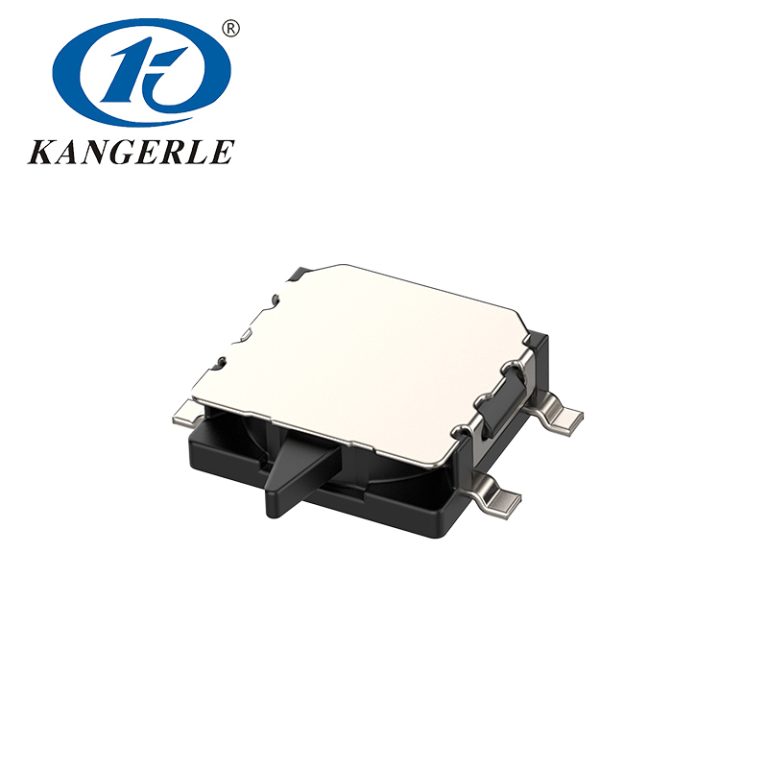

KANGERLE’s small detector switches show this setting skill: KANGERLE detector switches are tiny switches with special shapes. They offer safe contact and sensitive action.

Role of Surface Mount vs. Through-Hole Fixing Choices

Fixing style changes both assembly speed and physical steadiness on PCBs. This is key inside small home CO detector cases. Surface mount choices save space. Through-hole types anchor better against bumps. This matters for wall units handled daily.

ZHEJIANG KANGERLE ELECTRONICS CO. LTD delivers exactly built rocker switches. The KCD3-11L series of rocker switches have set action forces and flexible fixing choices. These meet strict electrical work standards. Global OEMs in life-safety fields demand this.

What Key Safety Rules Affect Rocker Switch Use in CO Detectors?

Meeting worldwide rules ensures rocker switches in carbon monoxide detectors hit basic safety needs. This is essential for global approval.

Meeting Global Electrical Standards (UL, IEC)

UL (Underwriters Laboratories) and IEC (International Electrotechnical Commission) rules set limits. These cover insulation strength, insulation resistance, flame slowing, contact gaps, and physical endurance. All are key marks for parts in life-saving tools like CO detectors.

Makers must test their goods against these points before putting them in approved devices sold worldwide.

Needs for Separation, Insulation, and Voltage Levels

Good separation between conductive paths lowers short-circuit risks. This could happen from wetness or solder bridges during assembly. Voltage levels must be higher than working voltages by a safe amount. This handles surges from grid issues or lightning strikes.

KANGERLE’s lit waterproof types add extra safety layers. They fit both home indoor use and factory places needing more toughness.

Rule Guides on Setting Tests and Long Life

Switches face faster aging tests. These include temperature cycles, damp chambers, dust entry tests. Sometimes salt spray testing is used too. These copy real-world aging over product lives beyond 10 years.

ZHEJIANG KANGERLE ELECTRONICS CO. LTD lines up its making with UL/IEC standards. The KCD3-11L series of rocker switches use modern insulation methods and long-life test steps. This ensures they meet strict rule sets for carbon monoxide detection systems worldwide.

How Do Surroundings Change Rocker Switch Results?

Surrounding toughness decides if a rocker switch keeps working under shifting conditions. This is essential for carbon monoxide detectors used in different weathers.

Fighting Wetness, Dust, and Heat Changes

Moisture entry can rust contacts. This raises resistance or causes open circuits. Dust build-up might block mechanical movement. Extreme heat can bend plastic cases. All these can cause device failure if not fixed during design.

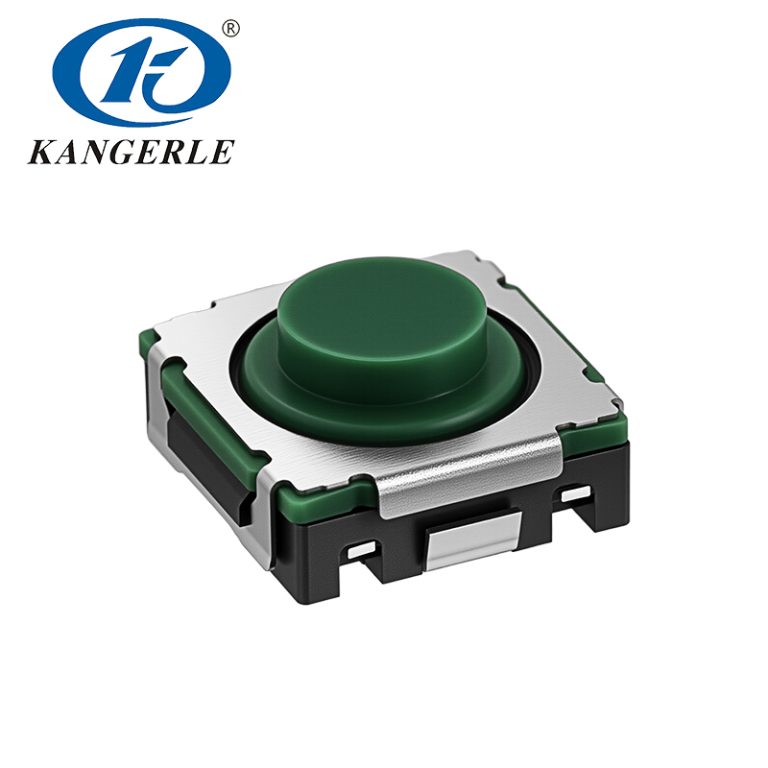

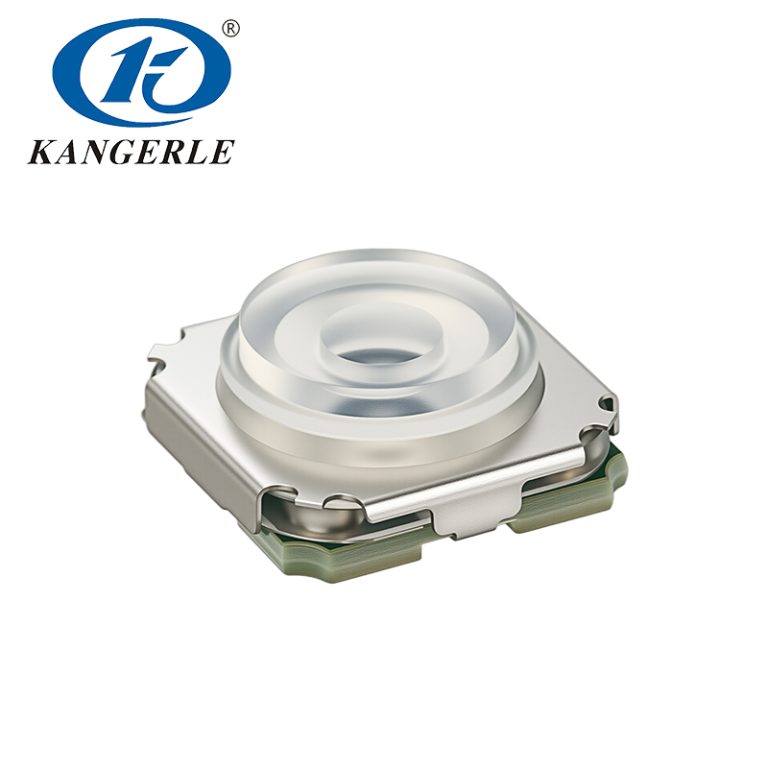

We have normal type, waterproof type and lit type rocker switches. These types are built to fight common surrounding stresses. They face these in home setups like kitchens or garages where dampness is common.

Keeping Steady Work in Homes and Factories

Switches in homes must handle small heat shifts. Those near heaters or boilers face higher heat. This needs heat-stable materials. Factory sites add more issues like shaking. This calls for stronger fixing points. Electrical noise needs shielded shapes.

Safety Parts to Reduce Outside Disruption

Modern shapes may add electrical noise blocking layers. Grounding tabs built into the case structure help too. Waterproof seals stop liquid entry. Sunlight-resistant plastics allow outside use. Each part fits exact use cases without hurting electrical soundness.

The KCD3-11L series of rocker switches add waterproofing tech, rust-proof materials, dust-proof sealing ways. All are tested heavily. They promise smooth results anywhere. This applies to their rocker switch answers used in gas detection systems.

What Gains Come from Custom Rocker Switch Answers for Detector OEMs?

Custom work lets original equipment makers (OEMs) make their products stand out. It also tunes performance for exact needs in carbon monoxide detection markets.

Changing Design Points for Exact Needs

OEMs might need special lever lengths or terminal angles. This depends on case limits. Others may want double jobs. Think mixing power control with LED lights in one small unit shape.

This set of switches gives a custom service. You can pick varied action ways, travel lengths, lever sizes, and terminal types for uses.

This bend cuts redesign costs at PCB level. It also makes end-use more comfy through custom touch feels. These suit target groups like older users.

Building Brand Difference Through Custom Looks

Custom colors matching company brands or laser-cut symbols showing function lift seen value. They also keep job clarity in low light. Detectors are often placed near utility rooms with poor light.

ZHEJIANG KANGERLE ELECTRONICS CO. LTD helps OEMs through custom choices. These include action way changes, lever shape shifts and look improvements. These lift both technical fit and brand image across many detector setups used globally now.

Who is Zhejiang Kangerle Electronics Co., Ltd.? What are the advantages of their products?

They are a known maker focused on electronic switching answers. Look at ZHEJIANG KANGERLE ELECTRONICS CO. LTD’s Skill in Rocker Switch Making.They have KCD3-11L series of rocker switches which are used in carbon monoxide (CO) detectors. The KCD3-11L series of rocker switches offers the following advantages. First, its all-silver contacts effectively improve current stability and provide exceptional durability. Second, its gold-plated legs minimize resistance and maximize stability. Its stability persists over time, making it ideal for use in instruments requiring precision testing. Third, as a rocker switch, its compact size makes it suitable for use in small handheld air quality monitors.

They take heavy current loads and come with varied terminal types.

Their know-how goes beyond common uses into special fields like gas detection. Steady results are critical there.

Promise to Quality Checks and ISO-Approved Making Steps

Through ISO-approved lines, they stress quality checks at each stage. This runs from raw material checks to final packing. KANGERLE keeps tight tolerances. These are vital for parts in life-safety tools like carbon monoxide alarms.

Long Ties with Worldwide Carbon Monoxide Detector Makers

Their solid history includes work with top OEMs. These rely on steady supply chains backed by tech help teams. These teams can deliver custom answers fast across global shipping networks. These stretch from Asia-Pacific zones up to North America & Europe.

Final Thoughts

Rocker switches are vital inside carbon monoxide detectors. They control power flow steadily under changing conditions. They also allow exact user action through touch feedback systems built for long life.

By following worldwide rules and offering custom building skills,

ZHEJIANG KANGERLE ELECTRONICS CO., LTD stays a trusted partner. It backs next-step advances across gas sensing tech worldwide.

Common Questions

What makes a rocker switch good for carbon monoxide detectors?

A fitting rocker switch handles heavy currents well. It gives steady mechanical feedback after many uses. It seals against wetness and dust. It also meets UL/IEC rules needed for life-safety tools.

Can rocker switches be changed for special detector shapes?

Yes; makers like ZHEJIANG KANGERLE give custom services. These include lever length changes,terminal setups,and look tweaks made just for gas detection systems.

How often should rocker switches in CO detectors be checked or changed?

Regular checks every 6–12 months during planned upkeep are wise.Change times depend on use but usually match the full product life (5–10 years).